VS 320 SV 14 T

Packaging machine - VS 320 SV 14 T

Pictures

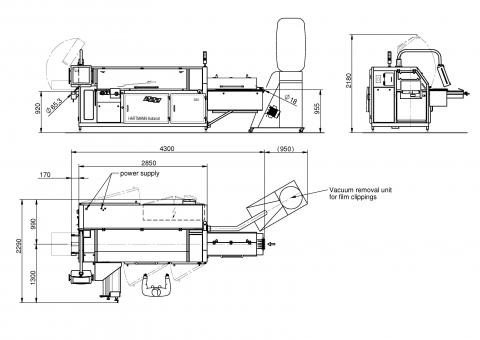

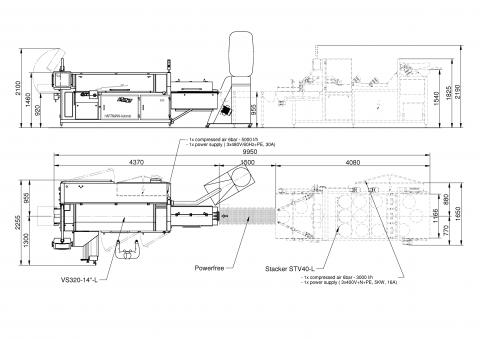

Drawings

Standards

Standard specification

|  |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Footrests without dowel holes |

| Conveyor system with servo driven speed |

| Longitudinal feed: Type `Tortilla-Infeed` with stoppers, lifts and cover |

| Transfer line with pusher dogs, base plate made from plain non-stick coated stainless steel |

| Lateral guides, plain stainless steel |

| Lateral guides above transfer line, manually adjustable by handwheel |

| Substitiution of bag air aspiration device |

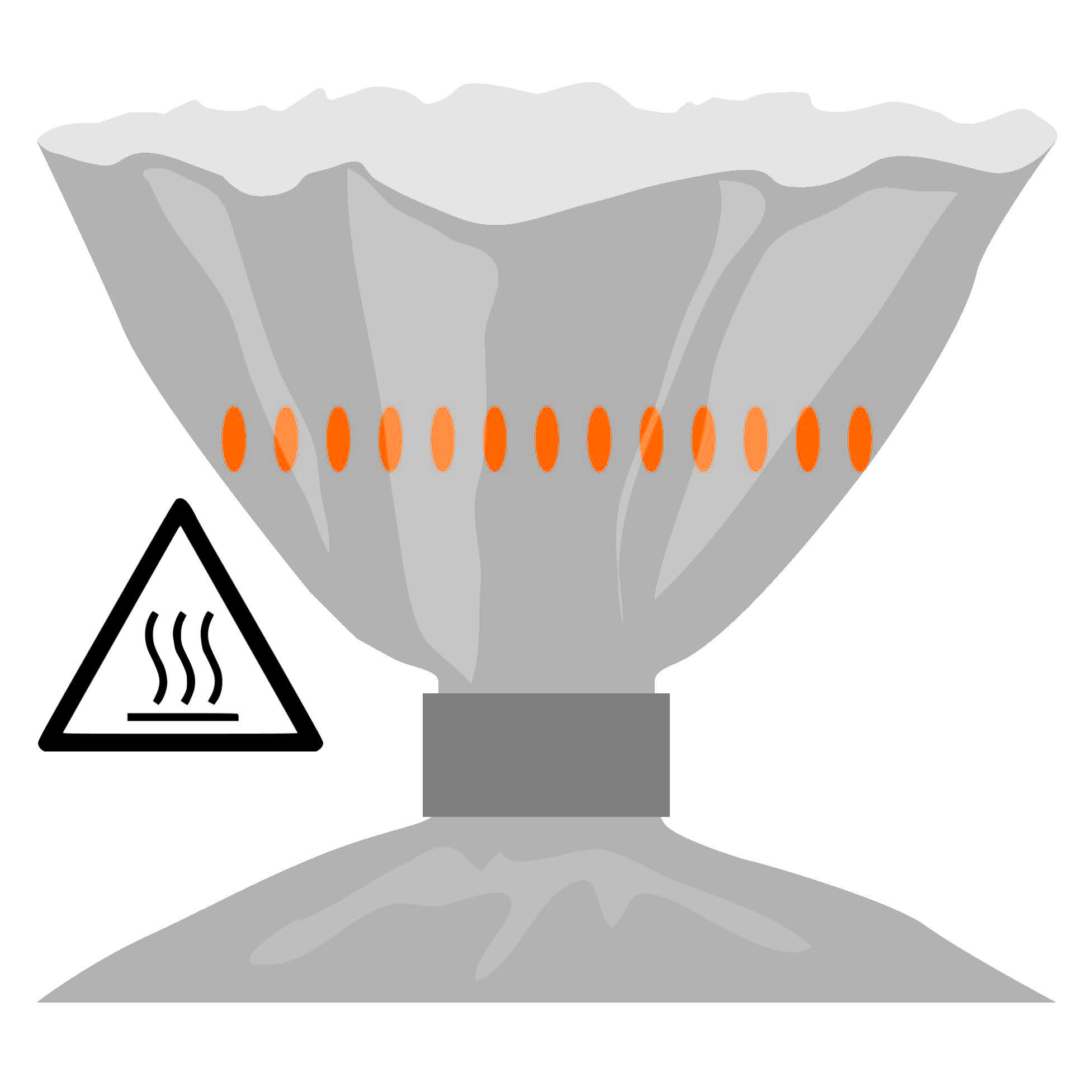

| Top pressure cussion and bag spreading instead of bag aspiration |

| Integrated side channel blower device |

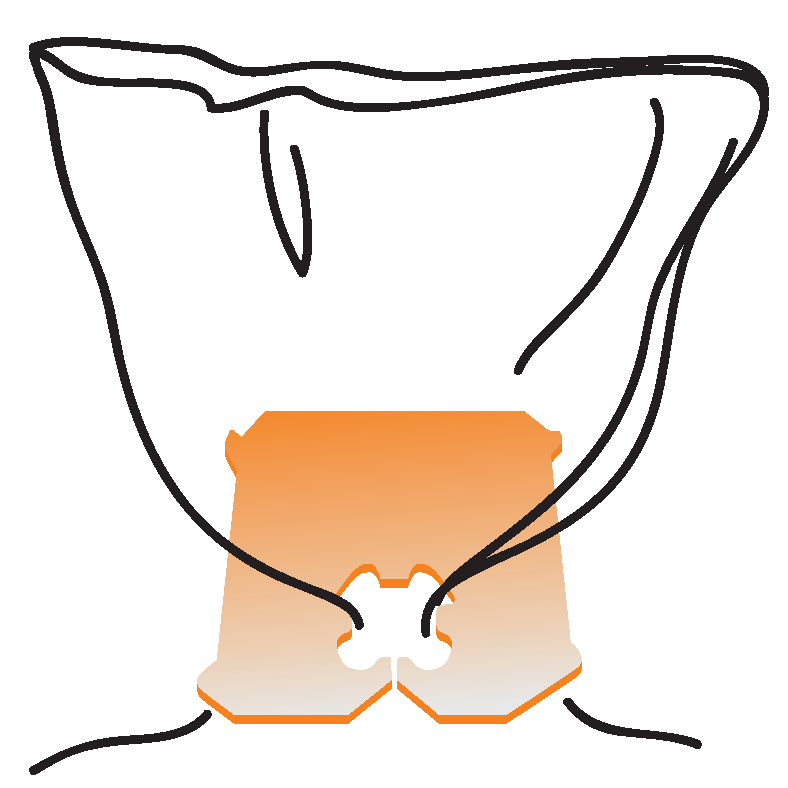

| Upper product holder - twin |

| Bottom product holder |

| Twin bag lifting device |

| 1st set of spreading plates for bag opening |

| 2nd set of spreading plates for bag opening |

| Wide spreading plate carriage for special applications |

| Non-stick coating for machine components which get in touch with the product |

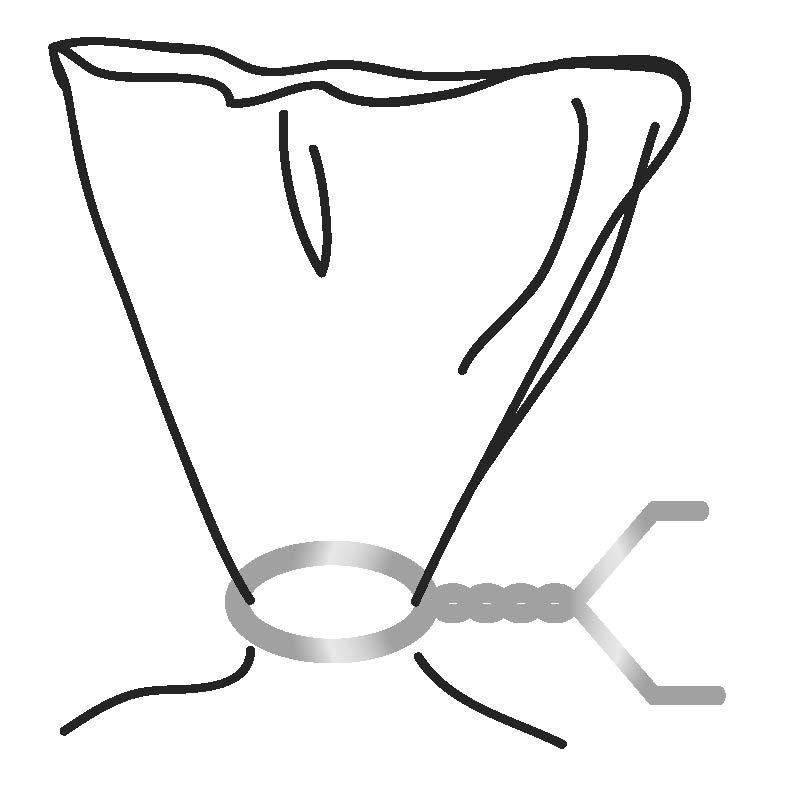

| Automatic bag magazine for extra-fast stack changeover `ABM-70 Twin S ` for straight U-shaped brackets and cropped U-shaped brackets |

| Automatic controlled switch-off at empty bag magazine |

| Automatic infeed and positioning of the next batch of bags |

| Protection hood for bag magazine - Stainless steel triangle hood and curtain |

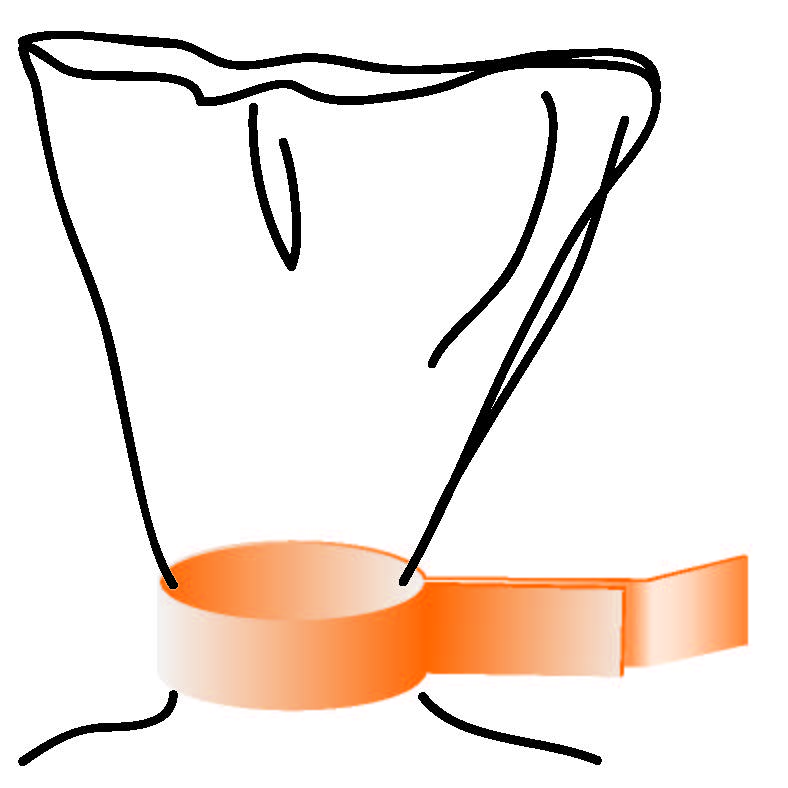

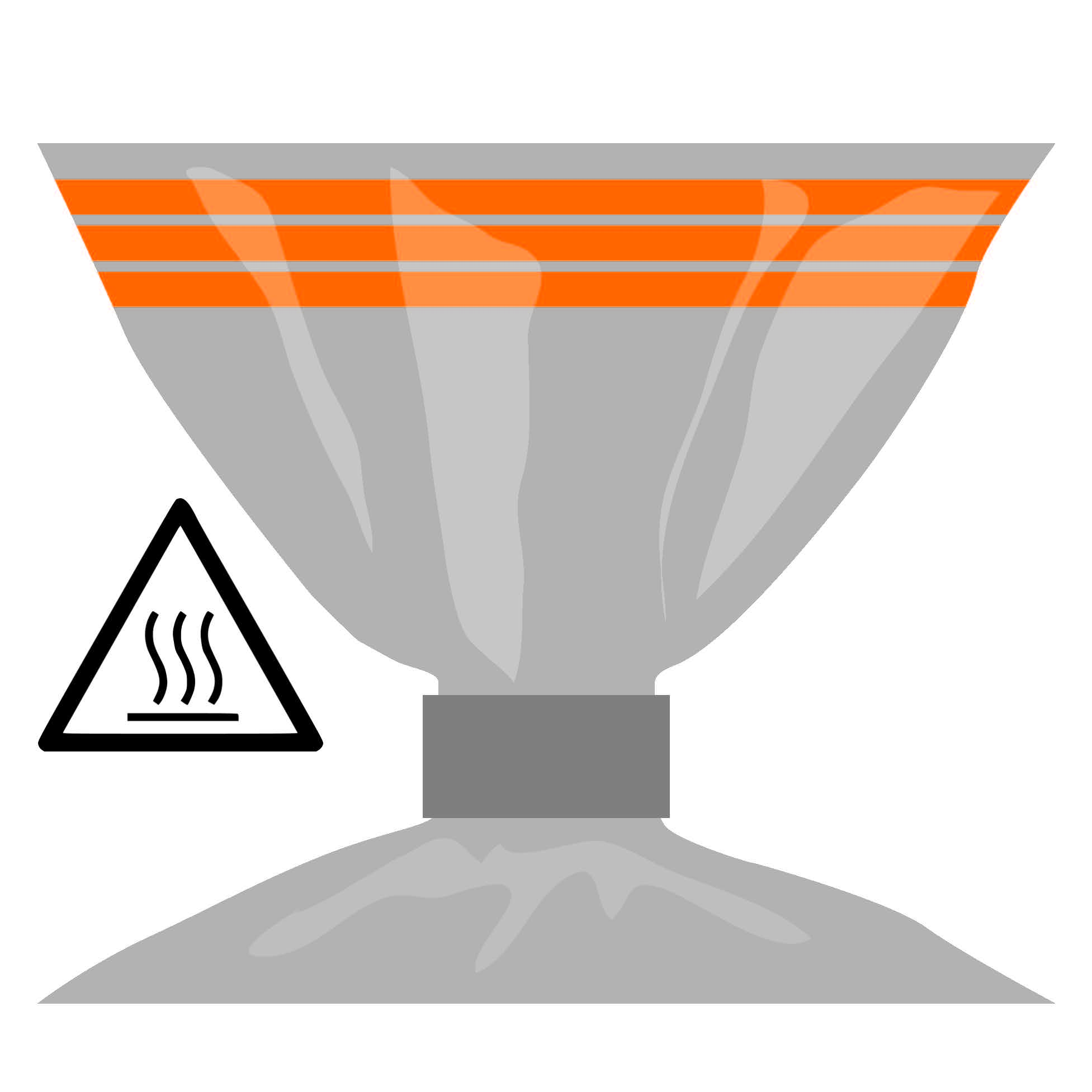

| Sealing aggregate, pulsed heating of sealing wires - PE-foils |

| Cutting off the foil overhang after sealing |

| Suction device for cut off foil residues |

| Special in line discharge conveyor, 2 lanes for flat, round bread |

| Sterile filter for sterilization the compressed air coming into contact with the products |

| Signal lamp - red light / green light |

| Signal horn |

| Switch cabinet with hasp locking |

| Switch cabinet with air-conditioning |

| Comfort-operating panel, rotatable with support arm system |

| Controls + touchpanel Allen Bradley |

| Servocontroller Omron |

| Automatic Stand-By in case of missing products |

| Remote service, VPN-Switch INSYS, (Master unit) |

| Voltage modulation, 3x 1 phase, input 480V |

| Isolating transformer |

| Electric execution according to UL-specification |

| Operating language and labels in English language |

| Operating manual in English language |

| Spare parts catalogue in English language |

Optionen

Options

|  |

|---|

| Welded machine frame, stainless steel, standard (crank-rockers made of galvanized steel) |

| Protection hoods made of perforated stainless steel panels |

| Extension (915 mm) for inline infeed. Additional space for manually infeed |

| Illumination of the working area inside the machine |

| Sealing aggregate, permanent heated sealing plates, non-stick coated - PP-foils |

| Product control on discharge conveyor and press jaw, adjustable by hand wheel |

| In line discharge: Accelerator belt, length 750 mm, foldaway, fixed at machine door |

| Switch cabinet with service interface FrontCom® with LAN and power socket |

| Additional signal lamp |

| RFID - Panel access authorization per chip, 10 pieces with up to 5 authorization levels |

| RFID - Additional chip, 10 pcs. with up to 5 authorization levels |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

VS 320 SV 14 T

Fully automatic bag packaging machine for large diameter tortilla stacks. The machine's product-specific design meets the varied international packaging requirements. Tortilla stacks are packed into foil bags and sealed tightly inside the machine in a single operation.

The drive concept of the VS 320 SV 14 T machine guarantees a constant switching point accuracy for all functions and reduces maintenance to a minimum. By consistently separating the product work area from the drive, this machine design also meets all cleanroom requirements. Drive technology in a wide range via servo drives.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 4300 mm, Width: approx. 2290 mm, Heigth: approx. 1730mm, Working height: approx. 955 mm, Film collection container height: approx. 2550 mm |

| Weight: | 1600 kg |

| Product dimensions: | Length: max. 360 mm, Width: 360 mm, Diameter: max. 360 mm, Height: max. 60 mm |

| Capacity: | up to 3000 Packages/h |

| Speed: | adjustable |

| Controller: | Allen Bradley |

| Operating panel: | Touchscreen |

| Control voltage: | 24 V, DC |

| Frequency controller: | Allen Bradley |

| Servo-controler: | Allen Bradley |

| Pneumatic system: | Festo |

| Power supply: | 480 Volts / 60 cycles |

| Power consuption: | 4 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | Pre-manufactured plastic bags (PE, else on demand) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |

| Special: | Only for sealing closure |