CDS

Cassette distribution system - CDS

Pictures

Drawings

Standards

| |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Security light barrier for intervention protection |

| Footrests without dowel holes |

| Refuse of endpieces / heels. Adjustable plate in front of the slicer Outfeed |

| Plastic modular transport belt for product feeding |

| Outfeed equipped with chain conveyor with pusher bars, base plate made from structured non-stick coated stainless steel. |

| Outfeed with adjustable curved side guides |

| Swiveling device for portioned upright standing product slices by 90 ° - lying product slices |

| Unit for transfer in lengthwise direction, installed above the transport system, driven |

| Outfeed with plastic modular belt conveyor, closed smooth surface, driven |

| Product outfeed with lateral guides, manually adjustable |

| Terminal box |

| Signal lamp - red / green |

| Grid cable tray, open design |

| Control unit integrated in the slicing machine |

| Operating panel for manually input with Emergency -stop push-button |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

| |

|---|

| Protection hoods made of perforated stainless steel panels |

| Additional signal lamp |

| Frequency converter Allen Bradley |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

CDS

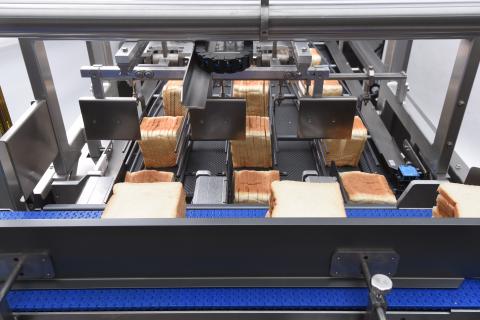

Fully automatic machine for forming portioned product stacks. The device is placed directly behind a slicer and takes over the cut in slices product. The end slices are rejected to the slicers's crumb box.

The sliced bread without end slices is divided into even portions at the infeed position and transported to a 90 ° swivel device. The portions are swiveled simultaneously in swivel cassettes. The position of the upright sliced and portioned slices changes in a horizontal slice stack. A rake system pushes the portion stacks onto a cross conveyor, which feeds the products to a subsequent packaging machine.

The clear and easily accessible design enables easy adjustment, cleaning and services.

| | |

|---|---|

| Dimensions: | Customer specific, Length: approx. 2800 mm, Width: approx. 1600 mm, Working height approx. 1050mm |

| Product dimensions: | Customer specific, Length: approx. 200 - 550 mm, Width: approx. 100 mm Height: approx. 100 mm |

| Capacity: | up to 3600 Packages/h |

| Speed: | adjustable, depending on the packaging machine |

| Controller: | Omron |

| Operating panel: | Touch panel /Touch panel of the slicer |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 400 Volts / 50 cycles |

| Power consuption: | approx. 1 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left / right |

| Protection class: | IP 54 |