HB 2

Horizontal band slicer - HB 2

Pictures

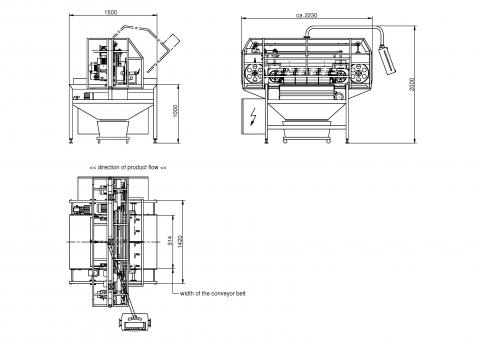

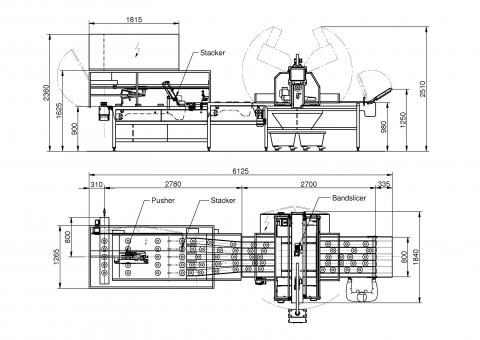

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, stainless steel, overall width transport system 840 mm |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Slides and/or funnels for bread crumbs |

| Footrests without dowel holes |

| Conveyor system with adjustable speed |

| Drive for slicer(s) with frequency-converter adjustable speed |

| Plastic modular belt with anti-skip rubber surfaces at the bottom side |

| Plastic modular belt for top pressure with separate drive |

| Lateral guides above transport conveyor, manually adjustable 6-lanes |

| Horizontal cutting station to halve the product (single cut) or double cut |

| Manual height adjustment of cutting position and product height |

| Slicer adjustment by handwheel: Position of cut in height (2nd cut) |

| Set of band blade HB 2 2x |

| Spare set of band blade HB 2 2x |

| Collecting dip tray, on carriage |

| Equipment stops in case of blade break |

| Slicing compartment with additional sensors with mechanical safety locking for openings |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Contactor control system with switches |

| Control unit integrated in the bagging machine |

| Automatic Stand-By control system for behind located machines in case of missing products |

| Frequency converter Hitachi (Omron) |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Modular belt made of plastic with rubber lining at the bottom, 3-lane for knife guidance for thin products |

| Oiling system for double horizontal band saw |

| Scratching device for band blades |

| Collecting dip tray, manually removable |

| Signal lamp - red / green |

| Signal horn |

| Switch cabinet with air-conditioning |

| Frequency converter SEW, transport |

| Frequency converter Allen Bradley |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

HB 2

Automatic slicing machine for baguettes, hot dog and hamburger buns. The incoming products are transferred to an upper and lower belt and sliced either once or twice using separately adjustable and separately driven belt blades.

All guides, the slicing position, and the upper belt can be adjusted without tools. The products can be fed as sorted or unsorted.

The machine frame and all casings are made of stainless steel – important for long value preservation and good for easy and hygienic cleaning.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 2000 mm, Width: customer specific, working height approx. 1050 mm |

| Product dimensions: | Diameter / width: min. approx. 50 mm, Height: 20 - 80 mm |

| Capacity: | product specific |

| Speed: | adjustable |

| Speed of the slicer: | adjustable |

| Band slicer length: | customer specific |

| Controller: | Omron |

| Operating panel: | Switches and buttons (line control- touchscreen) |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | approx. 5 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual /automatic |