EC 140

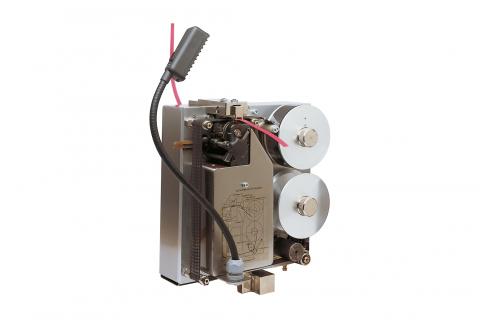

Closing unit - EC 140

Pictures

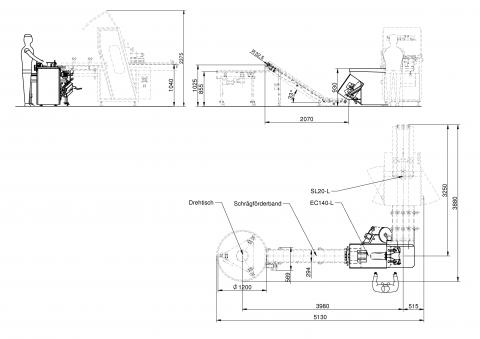

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, stainless steel, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Feets consisting of one pair of rollers and one pair of footrests |

| Drive with constant speed |

| Safety light barrier for manually loading |

| Adjustable stopping unit for products in the outlet, setting the closing position |

| Bag opening table with air blower device fixed to the machine frame |

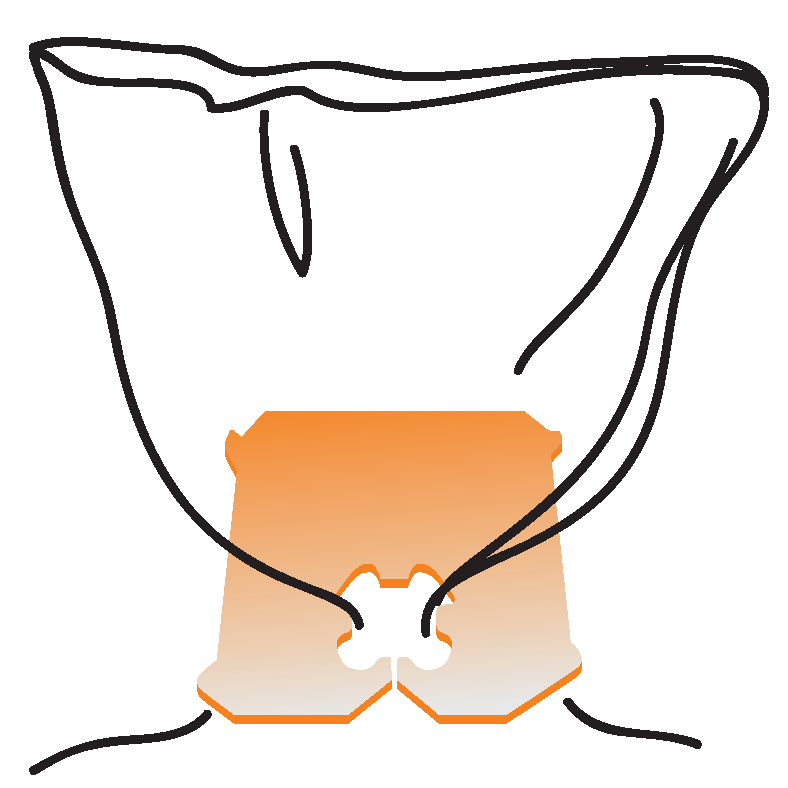

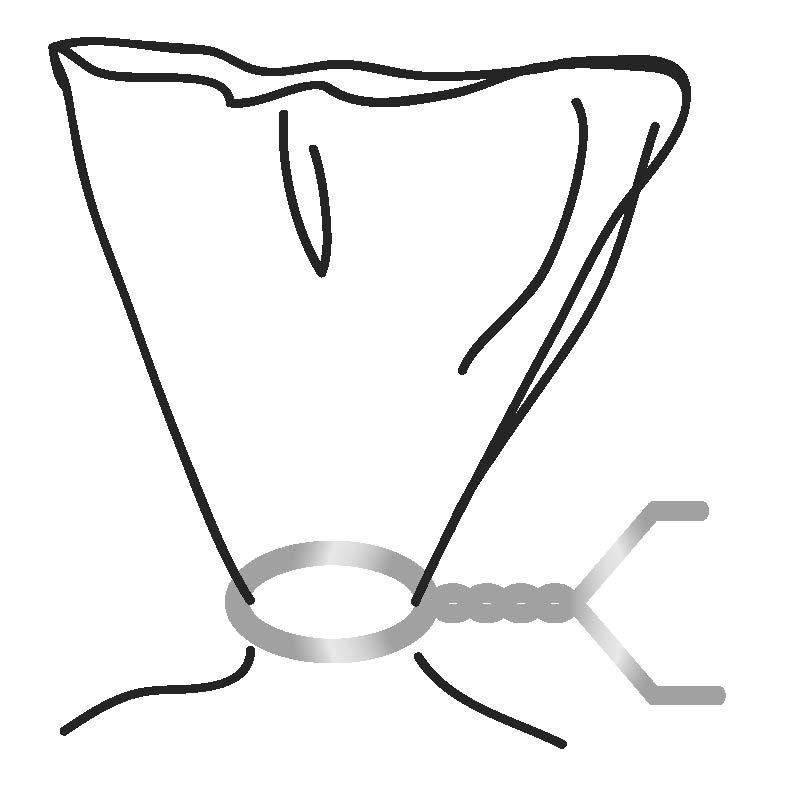

| Closing aggregate for clip |

| Single spool for closure rolls |

| Outfeed with slide |

| Product outfeed with lateral guides, manually adjustable |

| Connection by CEE-plug |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Contactor control system with switches |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| HPD-Printing on the clip, 6-digit |

| HPD-Printing on the clip, 9-digit |

| HPD-Printing on the clip, 13-digit |

| Preparation for retrofitting an HPD printer (without printer, printer assembly or commissioning) |

| Closing unit for closures Kwik-Lok® type J-NRP, Schutte Clipps G or equivalent |

| HPD printer, 6 digits for Kwik-Lok®, Schutte Clipps G or equivalent |

| Switch cabinet with air-conditioning |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

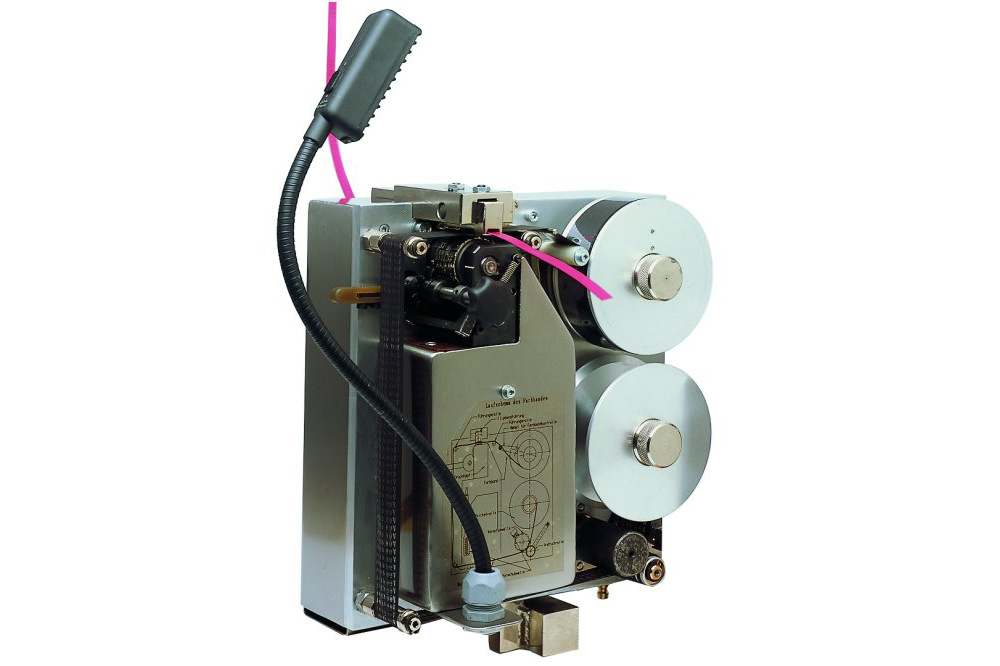

EC 140

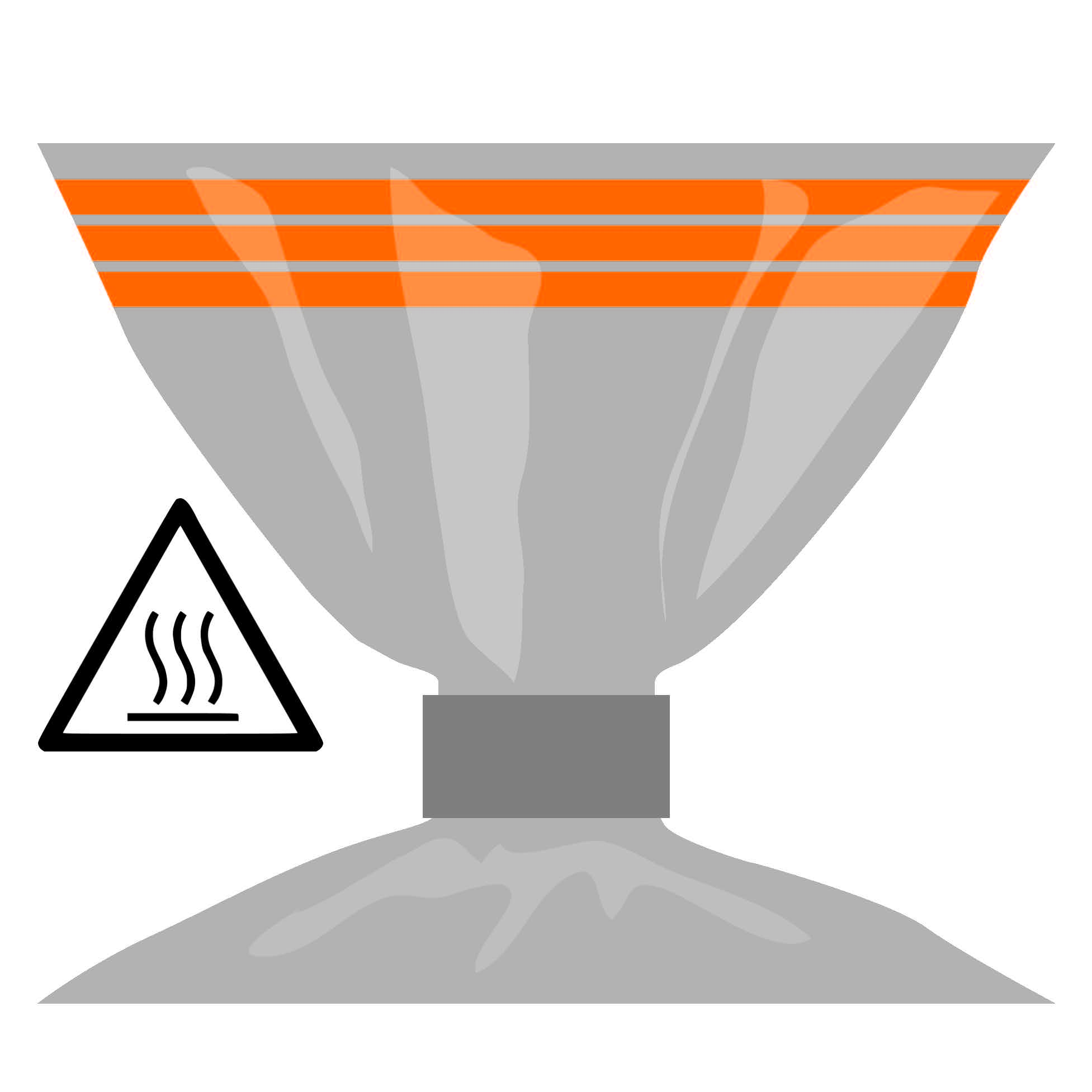

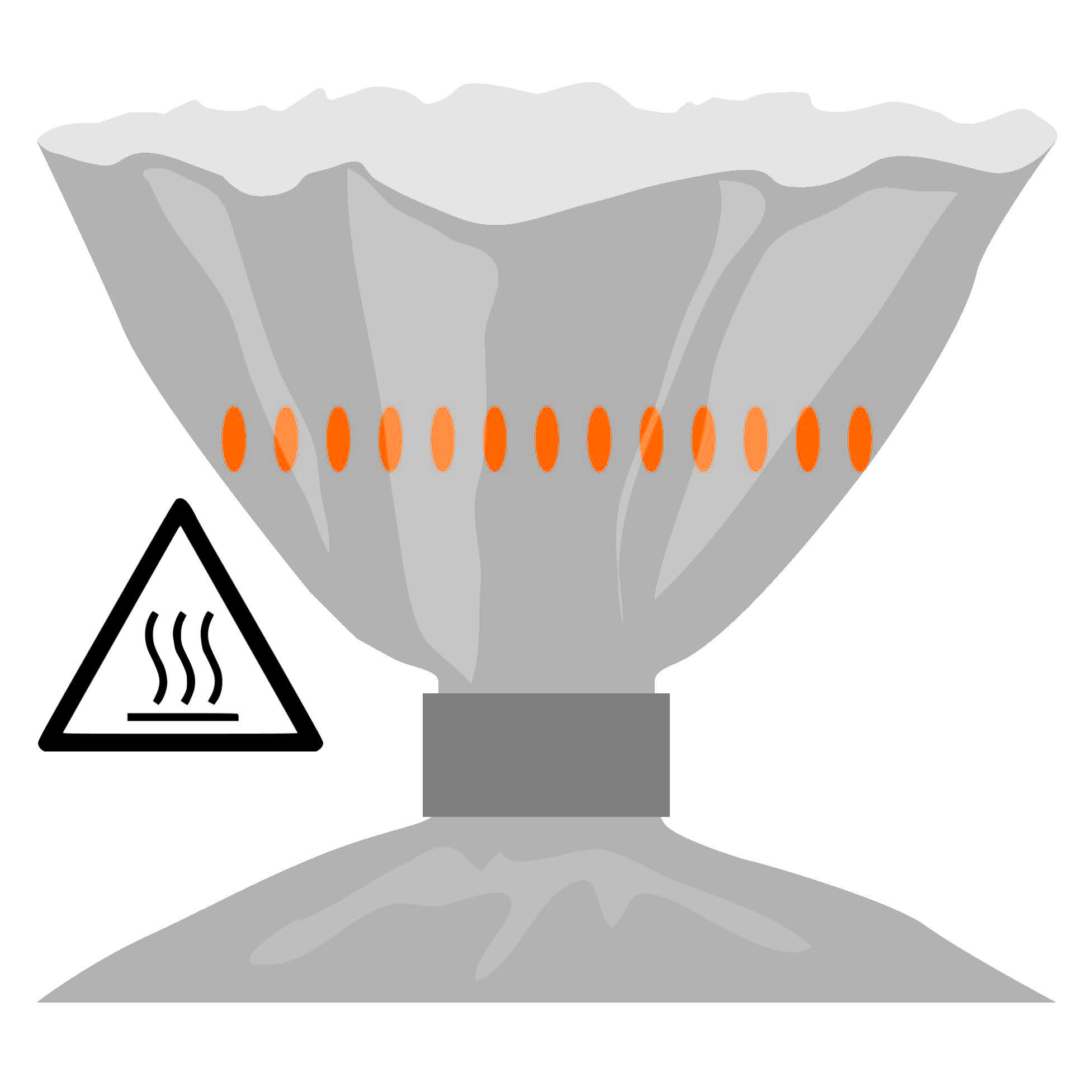

The EC 140 closing unit is an extremely versatile machine for manual filling into prefabricated plastic bags foil or paper bags. The machine frame and all casings are made of stainless steel – important for long value preservation and good for easy and hygienic cleaning.

Rollers and the compact design make this closing unit flexible, usable in almost any location. The inflation device pre-opens the bag, simplifying filling with products. The filled bag is precisely and securely closed in the subsequent closing station. Depending on the material size and thickness of the bags to be closed, the device can be equipped for different clip sizes or Kwik-Lok®.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 1630 mm, Width: approx. 1160, Working height: approx. 960 mm |

| Weight: | 235 kg |

| Product dimensions: | Length: up to 400 mm, Width: up to 180 mm, Height: up to 120 mm |

| Capacity: | up to 2700 packages /h |

| Speed: | depending on feed speed |

| Controller: | Contractor control |

| Operating panel: | Switches and buttons |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power consuption: | 0,8 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | Pre-manufactured plastic bags, or paper bags (paper with clip closure only) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |