GP

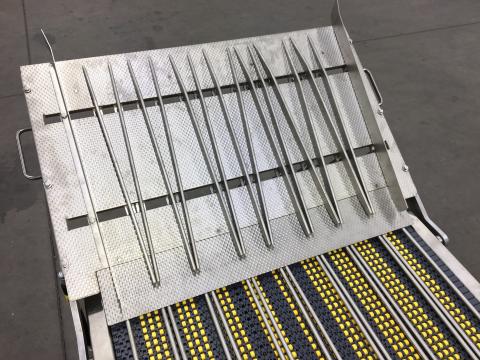

Grouping device - GP

Pictures

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, stainless steel, overall width transport system 840 mm |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Footrests without dowel holes |

| Drive by master shaft from following HARTMANN-machine |

| Conveyor system with adjustable speed |

| Slide for product feeding and alignment, tiltable |

| Infeed-accumulating plastic roller carpet, Azetal 1-lane with separate drives |

| Accumulating plastic roller carpet, Azetal 1-lane |

| Stainless steel lateral guides, manually adjustable, 6-lanes |

| Plastic modular belt below grouping device, 1-lane |

| Soft stopper rags for grouping of products, 6-lanes, driven, manually stepless adjustable by handwheel |

| Stopping units for products at the outfeed, driven, 2-lanes |

| Selector switch for manually feed lock for downstream machines |

| Signal lamp - red / green |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Operating panel for manually input with Emergency -stop push-button |

| Control unit integrated in the bagging machine |

| Automatic Stand-By control system for behind located machines in case of missing products |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Welded machine frame, stainless steel, overall width transport system 1100 mm |

| Switch cabinet located on top of the machine frame |

| Foot with swivel castors and lock |

| Driven plastic modular belt with slope for product feeding and alignment, tiltable |

| Stainless steel lateral guides, manually adjustable, 8-lanes |

| Stainless steel lateral guides, manually adjustable, 10-lanes |

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| Comfort-operating panel, rotatable with support arm system |

| Frequency converter SEW |

| SEW-Movigear within drive unit |

| Frequency converter Allen Bradley |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

GP

Device for semi-automatic grouping. Depending on the design of the device, the products are conveyed in tracks via a chute or a line distribution system.

There is a collection and buffering on accumulation stretches. A balanced distribution of the products on all lanes is carried out customer-specifically by manual control and manual or automatic control.

This is followed by a longitudinal grouping system of adjustable stoppers, which accumulate the corresponding batch length in each lane and release it for further transport.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: customer specific approx. 3000 mm, Width: 850 - 990 mm, Working height approx. 950 mm |

| Weight: | approx. 300 kg |

| Product dimensions: | Diameter / width: min. approx. 50 mm, Height: 20 - 80 mm |

| Capacity: | customer specific |

| Speed: | adjustable |

| Controller: | Omron |

| Operating panel: | Switches and buttons (line control- touchscreen) |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 400 Volts / 50 cycles |

| Power consuption: | min. approx. 0,75 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |