EC 102 B

Sealing unit - EC 102 B

Pictures

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard slope 20° |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Switch cabinet located on top of the machine frame |

| Protection hoods made of polycarbonate |

| Footrests without dowel holes |

| Drive with frequency converter |

| Infeed by transport belt and roller conveyor for slopes 20°or 30° |

| Lateral guides above transfer line, manually adjustable |

| Lateral guides above transfer line, manually adjustable by handwheel |

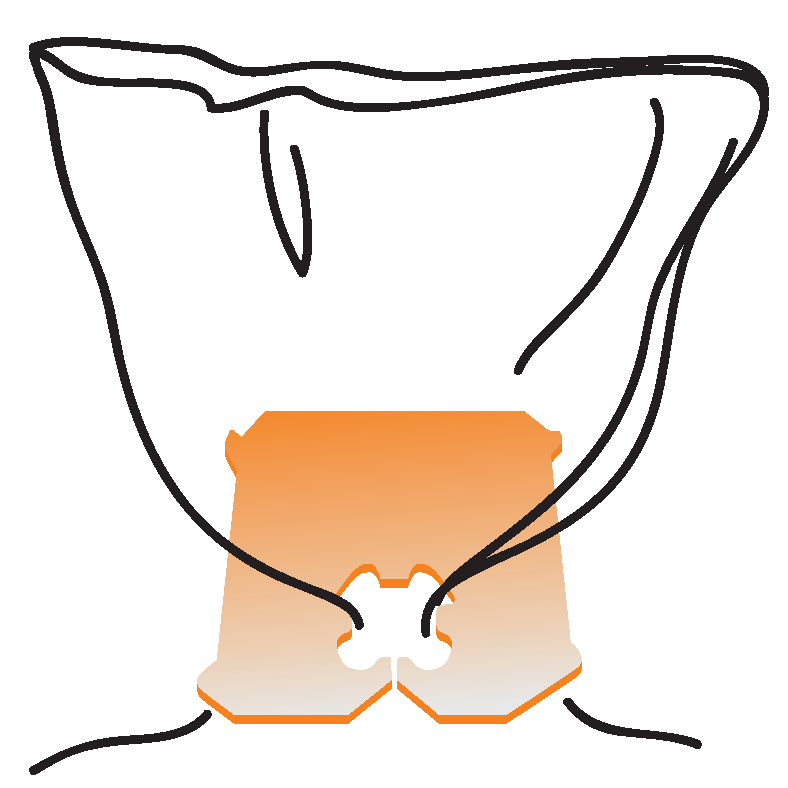

| Brushing rollers for smoothing the bag before closing |

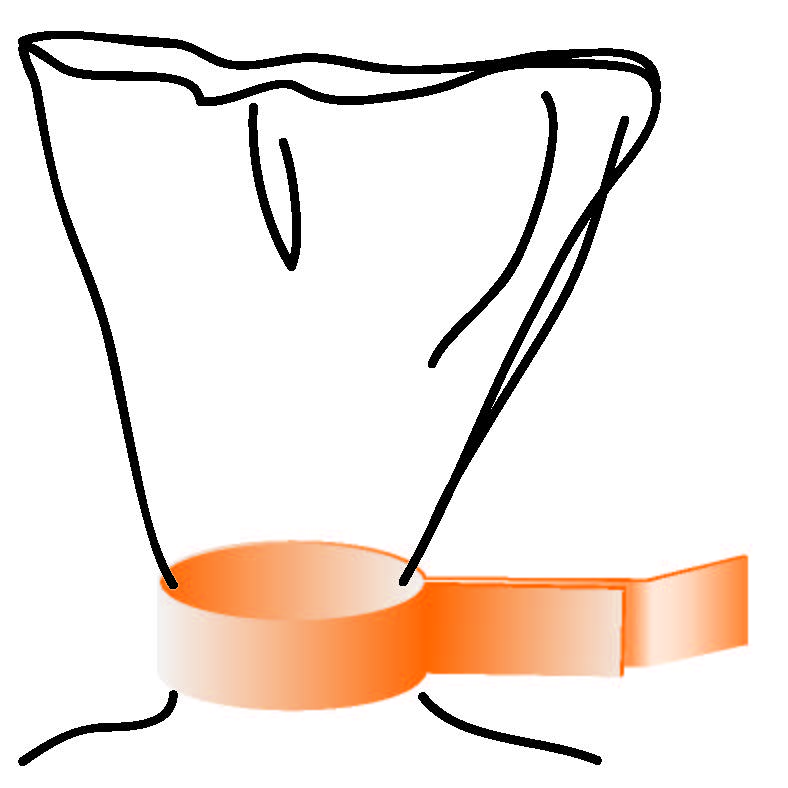

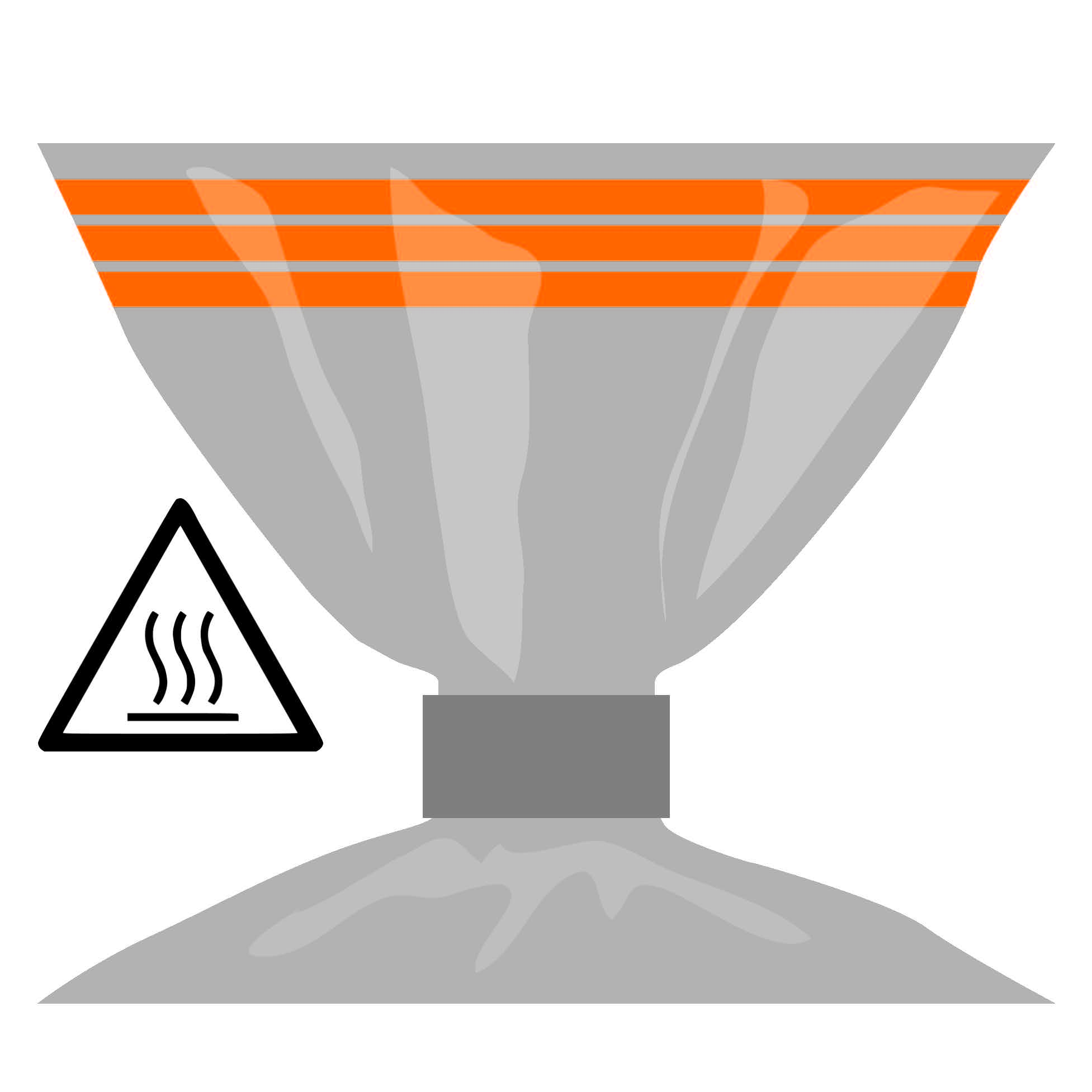

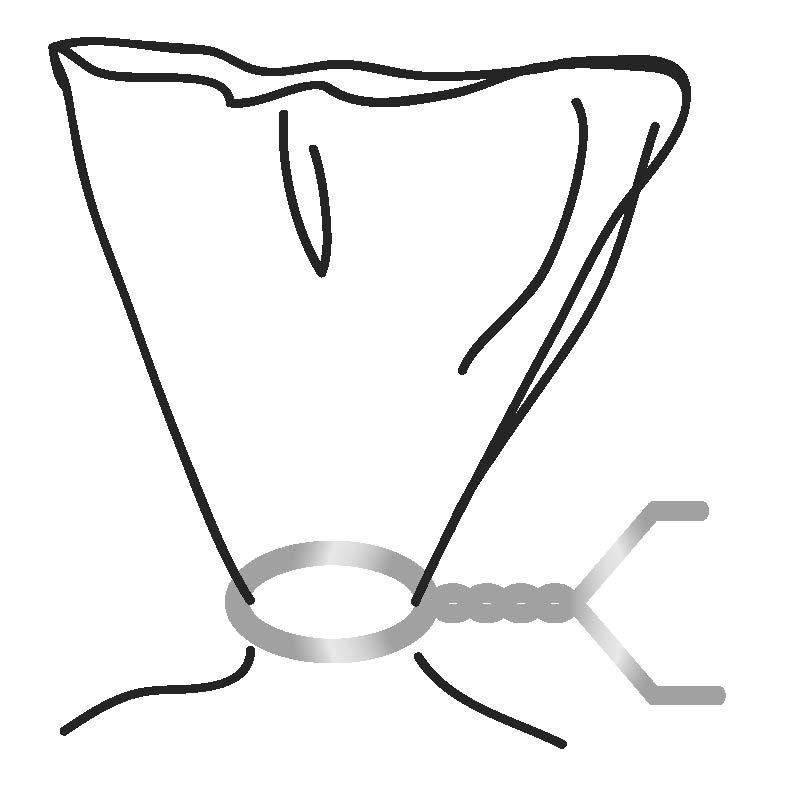

| Sealing aggregate, pulsed heating of sealing wires - PE-foils |

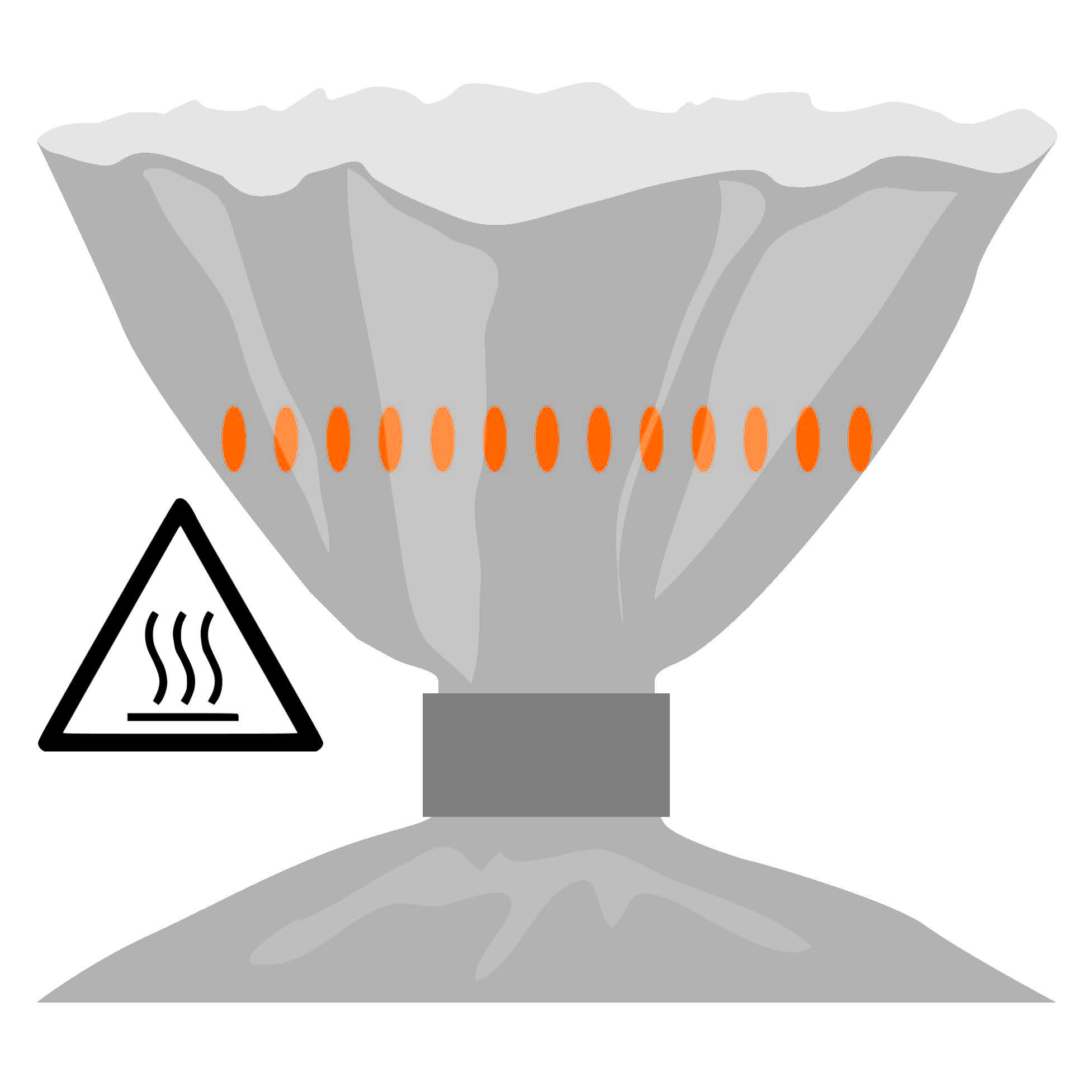

| Cutting off the foil overhang after sealing |

| Suction device for cut off foil residues |

| Outfeed with slide |

| Signal lamp - red / green |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Controls + touchpanel Omron |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard slope 30° |

| Welded machine frame, lacquered in stainless steel design colour, special slope 45° |

| Welded machine frame, lacquered in stainless steel design colour, special slope 60° |

| Welded machine frame, stainless steel, standard slope 20° |

| Welded machine frame, stainless steel, standard slope 30° |

| Welded machine frame, stainless steel, special slope 45° |

| Welded machine frame, stainless steel, special slope 60° |

| Protection hoods made of perforated stainless steel panels |

| Rotating swatter to smoothen the product bags |

| Sealing aggregate, permanent heated sealing plates, non-stick coated - PP-foils |

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| Frequency converter SEW |

| Frequency converter Allen Bradley |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

FAQ

EC 102 B

This sealing device is placed in an automatic packaging line behind a packaging machine in order to enable sealing of the bag ruffles without any restriction of the cycle capacity. The device consists of a feeder, a conveyor belt and a sealing station arranged at right angles. The conveyor belt is designed with an angle of inclination.

The filled bags are automatically transported to the sealing station. Brushes align the filled bag for optimum sealing results. A slicing device removes excess foil, which is removed by suction. All drive elements are directly accessible simply by opening the machine doors.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 1800 mm, Width: approx. 1200 mm, Height: approx. 1800 mm, Working height: approx. 950 mm |

| Weight: | 600 kg |

| Product dimensions: | Length: up to 400 mm, Width: up to 220 mm, Height: up to 120 mm |

| Capacity: | 3000 - 3600 package/ h |

| Speed: | adjustable |

| Controller: | Omron |

| Operating panel: | Switches and buttons |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power consuption: | approx. 2 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | Pre-manufactured plastic bags (PE, else on demand) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |