Scan 1

Density scanner - Scan 1

Pictures

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, stainless steel, standard |

| Welded machine frame, stainless steel, height adjustable 1.000 -1.100 mm |

| Hasp locking for cover panels |

| Footrests without dowel holes |

| Conveyor system with servo driven speed |

| Transport device equipped with function `forward run` and `reverse run` |

| Smooth transport belt |

| Stainless steel switch cabinet |

| Protective covers made of stainless steel panels |

| Radiation protection covers below the transport belts at the infeed side and outfeed side |

| Heavy duty infeed hood and outfeed hood |

| Infeed sensor holder inside the system |

| X-ray scanner for measuring dimensions and density of the products |

| X-ray camera: Function principle Tdi; 2048 x 128 Pixel |

| Power X-ray tube up to 600 W; 60 KV; 10 mA stepless adjustable |

| High performance industrial X-ray unit with metal-ceramic X-ray tube |

| X-ray tube cooling with heat exchanger system air/ water and internal water circulation |

| length measuring by light barrier |

| Customer-specific electric equipment: System designed in IP65 for wet cleaning |

| Signal lamp - yellow light (X-ray in operation), self-proofing |

| Working compartment openings with sensoring according to safety circuit PL e (performance level 4) |

| cable identification marking |

| Switch cabinet with hasp locking |

| Integrated emergency functions by hardware switches |

| Controls + touchpanel OCS |

| Control system for all real-time operations |

| High performance digital image processing |

| 15` touchscreen installed into a swiveable stainless steel housing |

| Switchable visualisation standard/ oversized letters |

| Menue-guided operation with plausibility check. Display of relevant actual data and settings |

| Malfunction message in plain text |

| Wide display of the production figures |

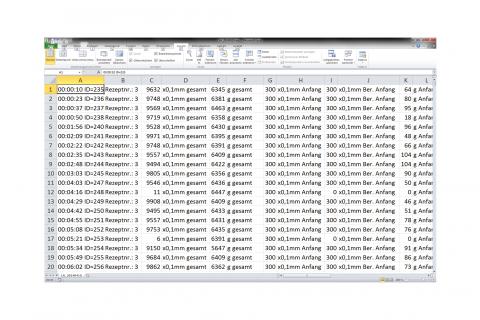

| Picture data storage as jpg-formate |

| Data transfer to internal FTP-server for doczumentation purpose of all production figures |

| software module `foreign objects detection` |

| Potential-free contacts for circuit signaling with local components |

| Ethernet-connection for remote maintenance and for line related statistic data |

| Signal adaption for the connection to the GHD Hartmann circular disc slicer |

| Electric execution according to CE-specification |

| Stainless steel dummy plugs and bolting |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

| Standard inspection boards with certificate: 2,5 mm stainless steel |

Optionen

Options

| |

|---|

| Radiation protection hood for density scanner system |

| X-ray tube cooling with heat exchanger system water/ water and internal water circulation |

| Additional signal lamp |

| Comscale4 software package `Basic` ®- connection of up to 5 OCS systems. Local MS-SQL-data server required |

| Software module `Report designer`: Supply of sample forms for statistics made within intervals, time frequence, spot checks or general purpose |

| Licence for the line with functions: Connection X-ray with the central Comsale®-module. Automatic safety storage of data for evaluations and analyses |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

FAQ

Scan 1

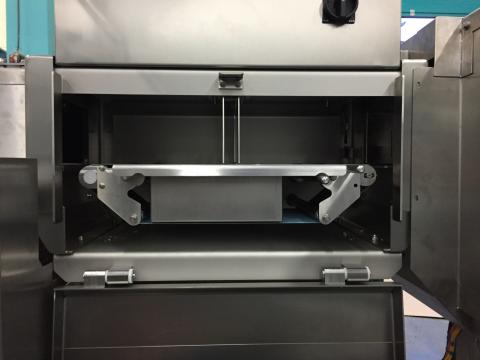

Industrial X-ray system in accordance with the TDI principle (Time Delay Integration) for unpackaged bread loaves for integration into the Hartmann slicing machine. Stainless steel body with solid tubular frame for better absorption of interfering vibrations.

Machine operation without active X-rays is possible via the customer's binary input. The evaluation software determines the local density profile within the bread loaf and transmits the relative slice weight in selectable steps of 0.1 mm of the loaf’s length beginning with the scanner's edge trigger position.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 720 mm, Width: approx. 850 mm, Height: 2100mm |

| Weight: | approx. 450 kg |

| Product dimensions: | Scanning width 320 mm, Throughfeed height: 180 mm |

| Capacity: | Speed max. approx. 0,5 m/min |

| Speed: | adjustable |

| Controller: | OCS |

| Operating panel: | Touchscreen |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | approx. 3 kW |

| Operating side: | left / right |

| Protection class: | IP 65 |

| Adjustment: | manual |