SL 30

Selectra slicing machine - SL 30

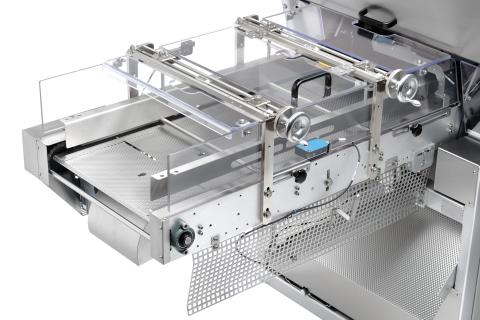

Pictures

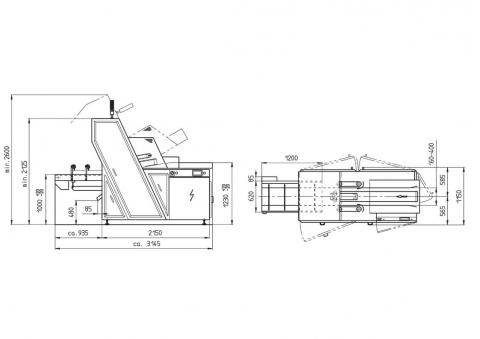

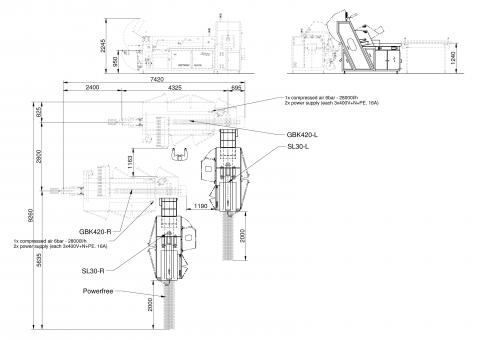

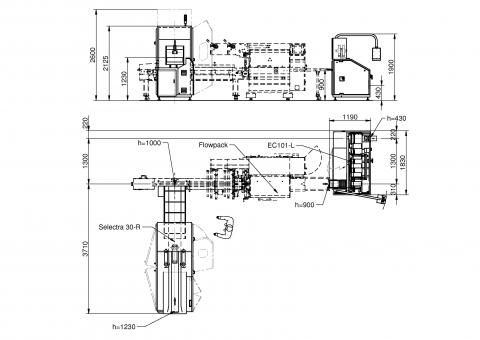

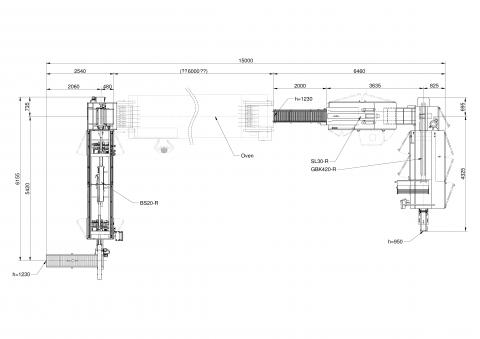

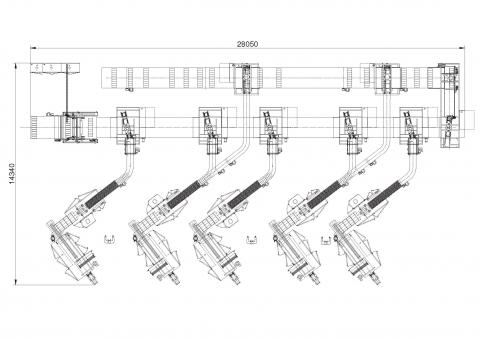

Drawings

Standards

Standard specification

|  |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard |

| Hinged door at the outfeed side |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Slides and/or funnels for bread crumbs |

| Footrests without dowel holes |

| Band-blade drive 5,5 kW |

| Conveyor system with adjustable speed |

| Accumulating belt in front of the Infeed, plastic roller carpet Azetal |

| Slicer - Bottom infeed: Plastic modular belt with anti-skip rubber surfaces |

| Product infeed with lateral guides, driven adjustable |

| Slicer -Infeed: Side guiding by driven belts |

| Slicer -Upper infeed by belt, products between 160 - 400 mm |

| Top belt height, driven adjustable |

| Slicing compartment with additional sensors with mechanical safety locking for openings |

| Equipment stops in case of blade break |

| Pneumatic blade tensioning device with automatic tension regulation |

| Blade guides with hardened round fingers for one constant slice thickness |

| Hand slider (POM with stainless steel handle) |

| Set of band blades 18x |

| Spare set of band blades 18x |

| Lower drum, standard |

| Catching tray for crumbs below slicing compartment, extendable drawer, stainless steel |

| Crumb scraper, pneumatic activated, installed at both drums |

| Illumination of the working area inside the machine |

| Plate at the infeed side of the slicer Outfeed |

| Slicer-Outfeed equipped with chain conveyor with pusher bars, base plate made from structured stainless steel. |

| Product outfeed with lateral guides, manually adjustable by handwheel |

| Catching tray for crumbs below outfeed position, extendable drawer, stainless steel |

| Signal lamp - red light / green light |

| Signal horn |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Operating elements located in the machine panel or door of the switch box |

| Controls + touchpanel Omron |

| Frequency converter Hitachi |

| Automatic Stand-By control system for behind located machines in case of missing products |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Welded machine frame, lacquered in stainless steel design colour. Clean room stage 1 - freely air flow |

| Welded machine frame, stainless steel, standard (supporting tube for drums made of galvanised steel) |

| Protection hoods made of perforated stainless steel panels |

| Protection hoods for clean room stage 5 - Full housing with clean air funnel |

| Band-blade drive 7,5 kW |

| Band-blade drive 11 kW |

| Accumulating belt for product feeding in front of the Infeed, total length 2,7m with foldable length 1,5 m, plastic roller carpet (Azetal) |

| 3 Sensors to detect twisted products - installed above the transport system |

| Additional set of blade guides with hardened round fingers for one constant slice thickness |

| Storage Trolley - Space for up to 5 additional sets of blade guides |

| Oiling system for band blades close to the lower pulley incl. oil pump, up to 40% rye content |

| Twin -oiling system for band blades close to the upper pulley and close to the lower pulley, incl. oil pump, more than 40% rye content |

| Blade sterilization by 2 UV-light radiators (Brand SterilAir, ET2230-4NA, Dose approx. 22-33 mW/cm²) |

| Refuse of endpieces / heels. Adjustable plate in front of the slicer Outfeed |

| Clean room stage 3/4/5: Crumb suction at the outfeed, guide plates and collecting funnel inside the slicer for crumbs and endpieces. Vibrating slide with channel for bread crumbs installed in the upper slicing housing. Pipeworks up to the central connection point for connection to local suction system |

| Switch cabinet with service interface FrontCom® with LAN and power socket |

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| Comfort-operating panel, rotatable with support arm system |

| RFID - Panel access authorization per chip, 10 pieces with up to 5 authorization levels |

| Controls + touchpanel Siemens |

| Controls + touchpanel Allen Bradley |

| Frequency converter SEW |

| Frequency converter Allen Bradley |

| Remote service, VPN-Switch INSYS, (Master unit) |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

SL 30

Fully automatic band slicing machine for toast and rye mixed bread. The cutting process takes place via heavy duty band knives with a length of 176 inches (about 4.5 m). The total length is tensioned between two hard chromed drums. The self-supporting, torsion-resistant tubular steel frame ensures smooth running of the machine. Generously designed doors and hoods allow both a good cleaning and maintenance access as well as a quick blade change.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 3145 mm, Width: approx. 1150 mm, Height: 2600 mm |

| Weight: | 1600 kg |

| Product dimensions: | Length: 160 - 400 mm, Height: 50 - 180 mm |

| Capacity: | up to 3800 products /h |

| Speed of the slicer: | adjustable between 180 - 400 m/min |

| Band slicer length: | 176 inch / approx. 4,5 m |

| Controller: | Omron |

| Operating panel: | Touchscreen |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | approx. 6,5 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | automatic/ manual |