GS 60

Reciprocating slicer machine - GS 60

Pictures

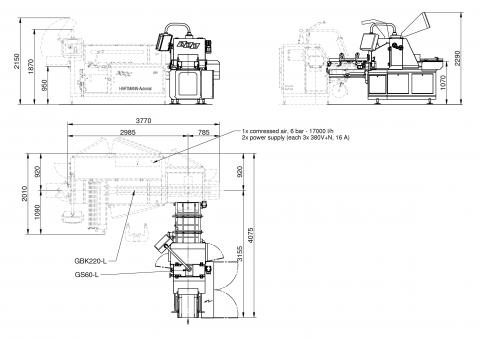

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, stainless steel, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Footrests without dowel holes |

| Slicer-blade drive 3 kW |

| Conveyor system with adjustable speed |

| Lateral guides in front of product infeed, manually adjustable |

| Product infeed with lateral guides, manually adjustable by handwheel |

| Top belt height manually adjustable by handwheel |

| Slicer - Bottom infeed: Plastic modular belt with anti-skip rubber surfaces |

| Slicer -Infeed: Side guiding by driven belts |

| Slicer -Upper infeed by belt, products between 160 - 400 mm |

| Infeed driven movable better access for cleaning and blade set-up |

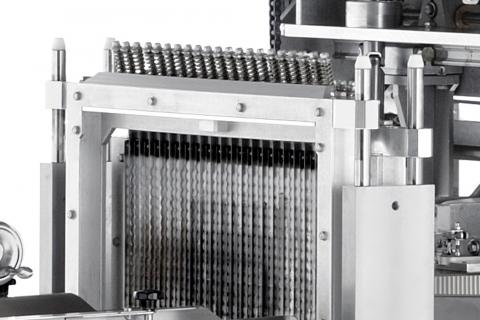

| Blade stroke 77 mm |

| Cutting frames with guiding plates for one constant slice thickness |

| Set of tools for blade exchange - Torque spanner and clamping lever |

| Spare blade set for reciprocate slicer 70 pcs. |

| Blade tensioning device with pre-adjusted spring-force |

| Equipment stops in case of blade break |

| Hand slider (POM with stainless steel handle) |

| Non-stick coating for machine components which get in touch with the product |

| Plate at the infeed side of the slicer Outfeed |

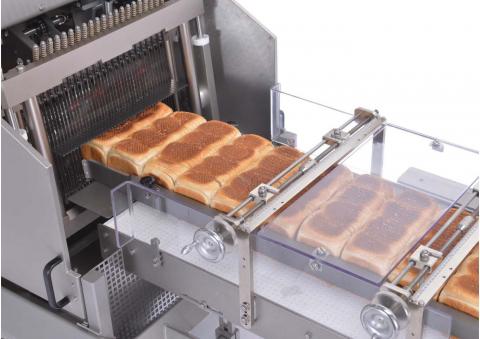

| Slicer-Outfeed equipped with chain conveyor with pusher bars, base plate made from structured non-stick coated stainless steel. |

| Product outfeed with lateral guides, manually adjustable by handwheel |

| Catching tray for crumbs below outfeed position, extendable drawer, stainless steel |

| Signal lamp - red / green |

| Signal horn |

| Switch cabinet with hasp locking |

| Switch cabinet with air-conditioning |

| Comfort-operating panel, rotatable with support arm system |

| Controls + touchpanel Omron |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Protection hoods made of perforated stainless steel panels |

| Slicer-blade drive 5,5 kW |

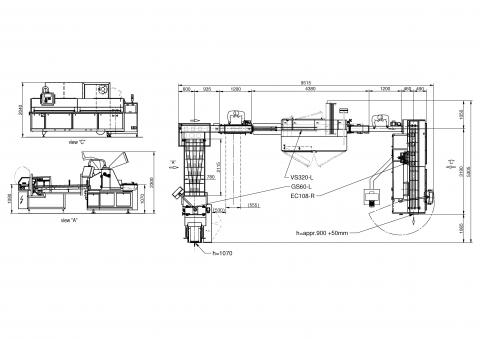

| Accumulating belt in front of the Infeed, stainless steel roller carpet (l= 1m) |

| 3 Sensors to detect twisted products - installed above the transport system |

| 2-lane-product feeding with individual upper belts and bottom belts. Adjustable side guides. Including product sensoring |

| Blade stroke 20 mm |

| Blade stroke 50 mm |

| Blade stroke 100 mm |

| Additional cutting frames with guiding plates for one constant slice thickness |

| Storage Trolley for up to 4 sets of additional cutting frames |

| Refuse of endpieces / heels. Adjustable plate in front of the slicer Outfeed |

| Outfeed with curved side guides to feed a flowpacking machine |

| Switch cabinet with service interface FrontCom® with LAN and power socket |

| Additional signal lamp |

| RFID - Panel access authorization per chip, 10 pieces with up to 5 authorization levels |

| RFID - Additional chip, 10 pcs. with up to 5 authorization levels |

| Omron control unit OPC-UA ready |

| Frequency converter Allen Bradley |

| Remote service, VPN-Switch INSYS, (Master unit) |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

GS 60

The GS 60 reciprocating slicer machine is a high-performance slicing machine for bread, sugary products, fruit bread and raisin breads. It cuts the products into slices of exactly the same size due to the vertical blade arrangement. The GS 60 is designed for continuous operation. The basis for this high performance is a Hartmann gearbox, which is equipped with special lubrication. In order to ensure optimum synchronisation with the packaging machine, the discharge conveyor is equipped with its own frequency-controlled drive. Combining it with the Hartmann packaging machines results in a perfectly coordinated overall solution with high flexibility and production reliability.

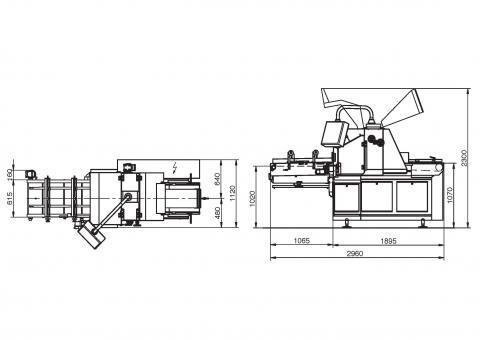

Technical specifications

| | |

|---|---|

| Dimensions: | Length: 2700 mm, Width: 1100 mm, Height 1620mm |

| Weight: | 1100 kg |

| Product dimensions: | Length: 160 - 400 mm, Height: 50 - 170 mm |

| Capacity: | up to 3600 products/ h |

| Speed: | adjustable |

| Speed of the slicer: | adjustable |

| Controller: | Omron |

| Operating panel: | Touchscreen |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | approx. 3,5 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual /driven |