AP 60

Portioning system - AP 60

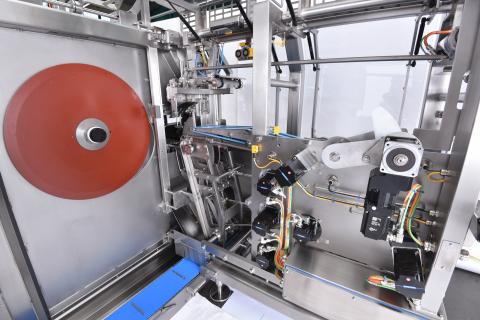

Pictures

Drawings

Standards

Standard specification

|  |

|---|

| Welded machine frame, stainless steel, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Slides and/or funnels for bread crumbs |

| Footrests without dowel holes |

| Conveyor system with adjustable speed |

| Servo driven rake device for grouping in pre-selected packages, 1-lane infeed |

| Holding down clamp system for products at the infeed, servo driven, 1-lane |

| Servo driven 90° turning device `Ente` for badges of upright standing slices in a horizontal position |

| Refuse of endpieces / heels, rake device and turning device servo driven moveable |

| Driven accelerator line, 3 parallel smooth plastic belt |

| Driven accelerator belt, smooth plastic belt conveyor |

| Servo driven turning device for products by 180° to position the slices bottom side in front direction, turning star exchangeable |

| Driven accelerator line, 3 parallel smooth plastic belt |

| Driven accelerator line, 3 parallel smooth plastic belt |

| Openings with additional sensors with mechanical safety locking for openings |

| Illumination of the working area inside the machine |

| Switch cabinet with hasp locking |

| Comfort-operating panel, rotatable with support arm system |

| Controls + touchpanel Omron |

| Frequency converter Hitachi |

| Servocontroller Omron |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

|  |

|---|

| Carriage for alignment guides, covers or other non-specific removeable parts - external wet cleaning |

| Exchange-turning compartment device for badges of sliced bread |

| Carriage for up to 4 exchange turning devices - for external wet cleaning |

| Catching tray for crumbs below machine, extendable drawer for cleaning, stainless steel |

| Omron control unit OPC-UA ready |

| Simultaneous process data feedback for fine adjustment of the slicing system. Packages weight data taken from a local OCS checkweigher system. |

| Control unit with OPC-UA, customer-specific data supply |

| Frequency converter SEW |

| Frequency converter Allen Bradley |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

AP 60

For automatic portioning and positioning of stacked bread slices. In combination directly behind a KM 600 P circular blade machine. Shared control and operating panel.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 1530 mm, Width: approx. 900 mm, Height approx. 1800mm |

| Product dimensions: | Width: 170 -190 mm, Height: 100 - 120 mm, 7 -12 slices/package (product specific) |

| Capacity: | approx. 50 -60 packages/min (product specific) |

| Speed: | adjustable, depending on the slicer |

| Controller: | Omron |

| Operating panel: | Touch panel |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Servo-controler: | Yaskawa |

| Pneumatic system: | Festo |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | approx. 2,5 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left |

| Protection class: | IP 54 |

| Adjustment: | automatic |