EC 150 V8

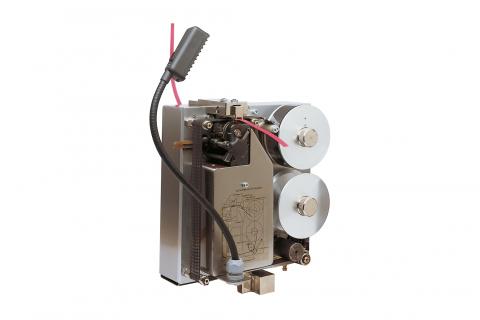

Closing unit - EC 150 V8

Pictures

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Foot with swivel castors and lock |

| Drive with frequency converter |

| Conveyor system with constant speed |

| Original equipment - Set of 8 bucket shaped guides |

| Adjustable closing position |

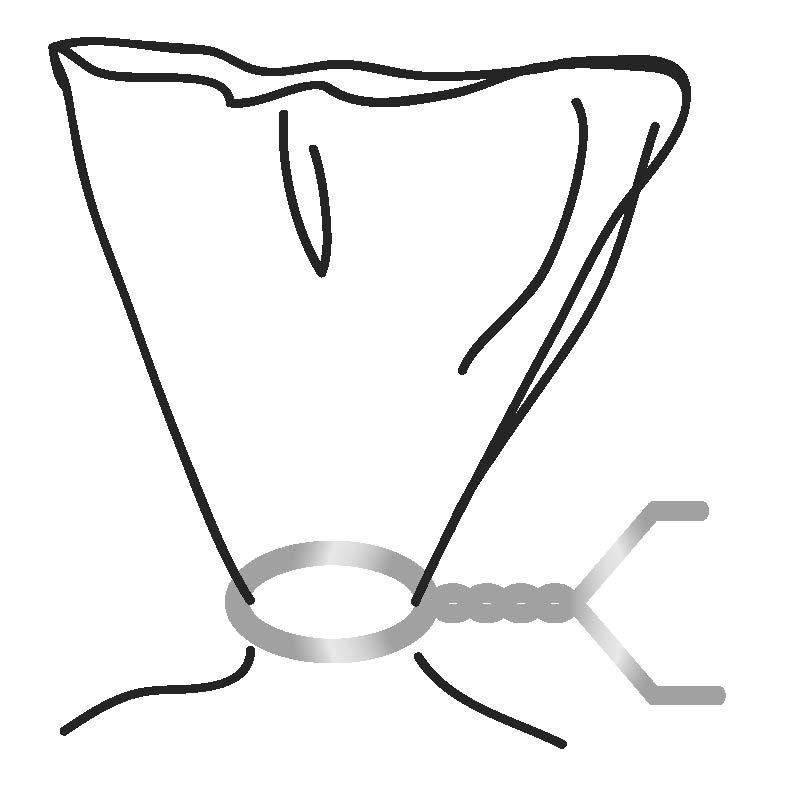

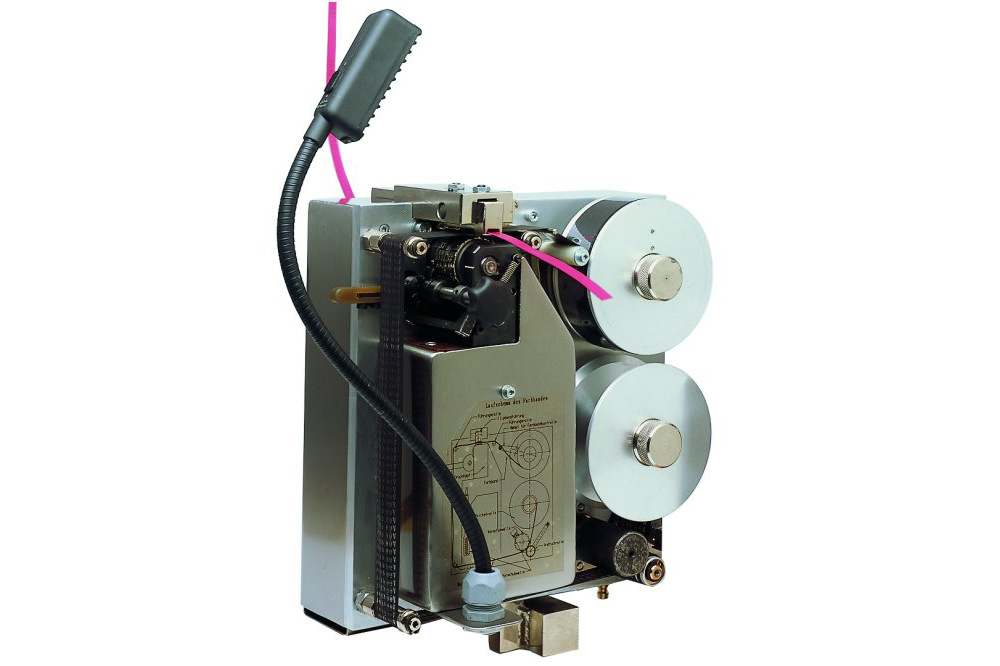

| Closing aggregate for clip |

| Single spool for closure rolls |

| In line discharge conveyor |

| Product outfeed with lateral guides, manually adjustable |

| Connection by CEE-plug |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Omron controls + switches |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Welded machine frame, stainless steel, standard |

| Additional equipment - Set of 8 changeable bucket shaped guides |

| Shaking base |

| Guillotine shears |

| HPD-Printing on the clip, 6-digit |

| HPD-Printing on the clip, 9-digit |

| HPD-Printing on the clip, 13-digit |

| Preparation for retrofitting an HPD printer (without printer, printer assembly or commissioning) |

| Switch cabinet with air-conditioning |

| Frequency converter Allen Bradley |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

EC 150 V8

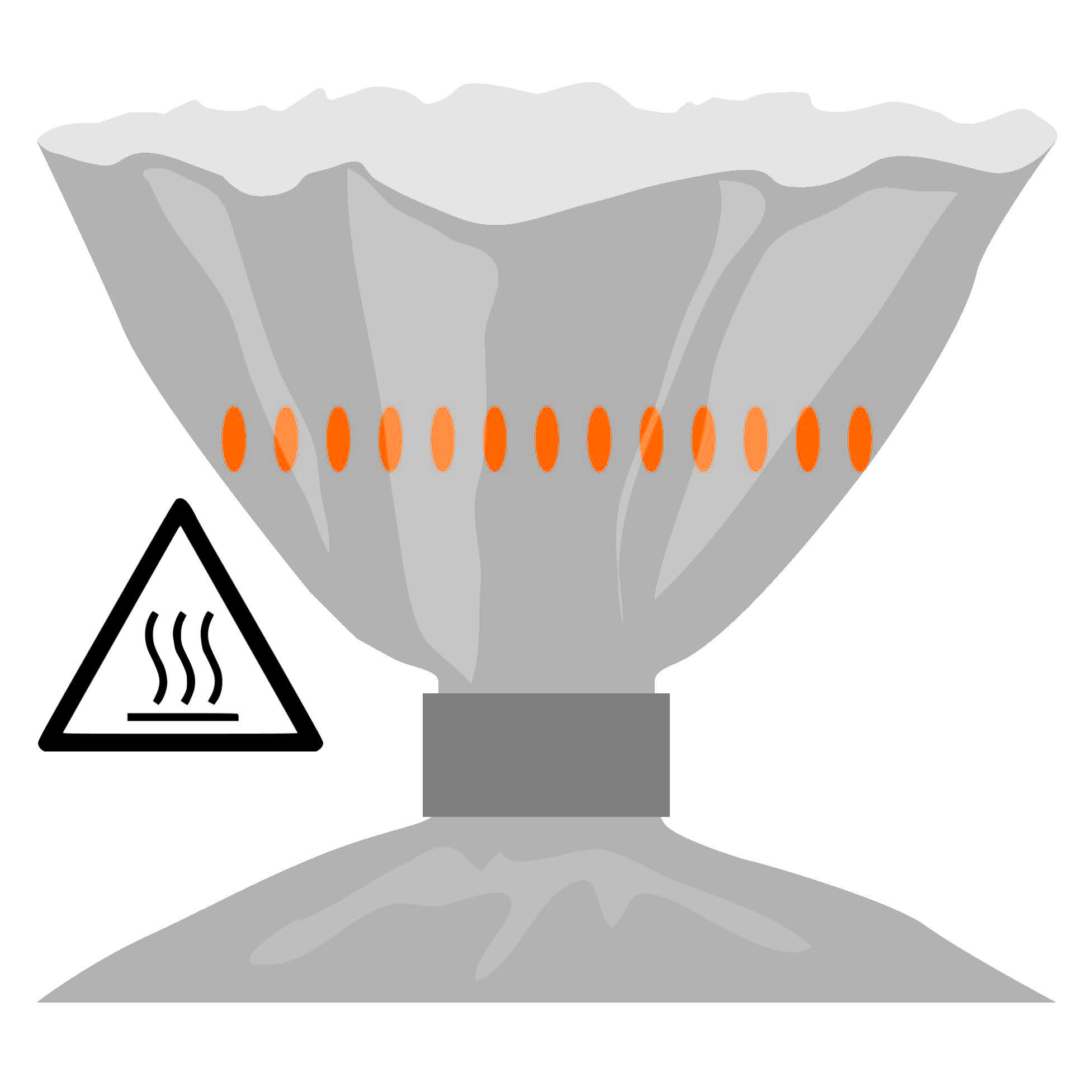

This device is particularly suitable for closing vertically filled bulk bag packages. Loading can be performed manually or by an upstream vertical packaging machine. Additional synchronisation is not necessary because the closing device has its own impulse-controlled drive.

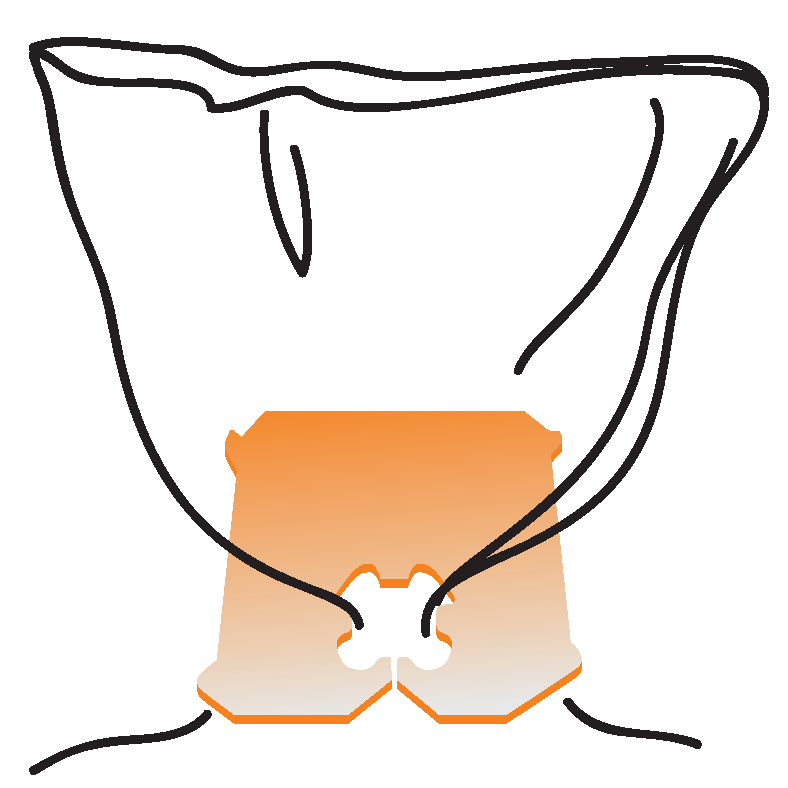

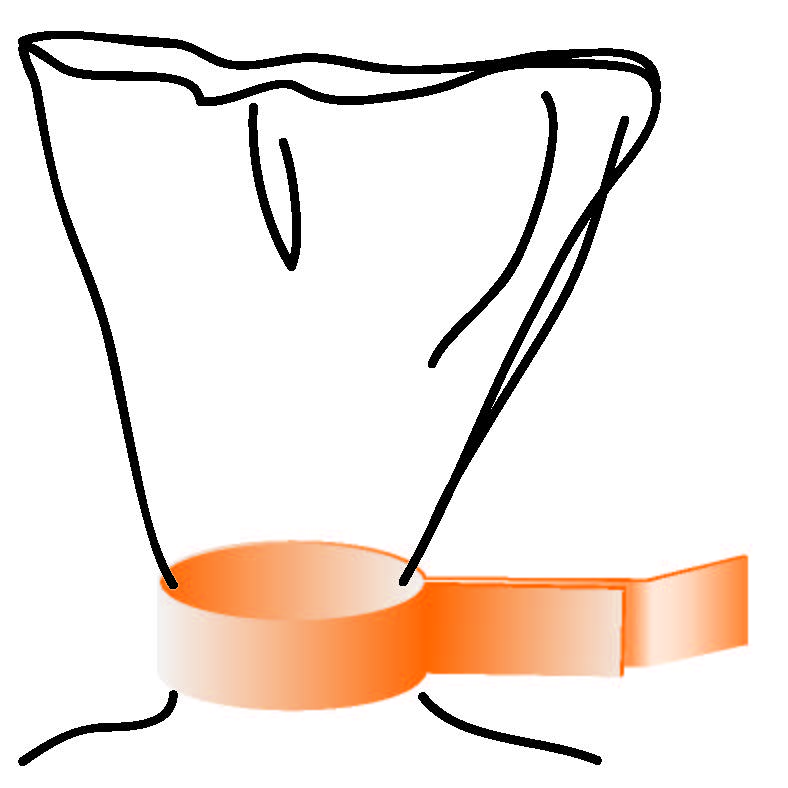

Using exchangeable format cups, the filled bags are guided in the closing device to the closing aggregate and to the discharge conveyor.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 1650 mm, Width: approx. 1140 mm, Height approx. 1210 mm, Infeed height: approx. 750 mm |

| Weight: | approx. 500 kg |

| Product dimensions: | Length: 80 -330 mm, Diameter: up to 150 mm |

| Capacity: | up to 3900 packages /h |

| Speed: | depending on feed speed |

| Controller: | Omron |

| Operating panel: | Switches and buttons |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power consuption: | approx. 2 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | Pre-manufactured plastic bags, or paper bags (paper with clip closure only) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |