EC 104

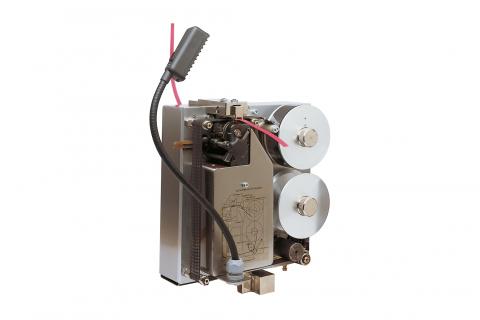

Closing unit - EC 104

Pictures

Drawings

Standards

| |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Foot with swivel castors and lock |

| Drive with frequency converter |

| Smooth transport belt |

| Lateral guides above transfer line, manually adjustable |

| Stopping unit for products |

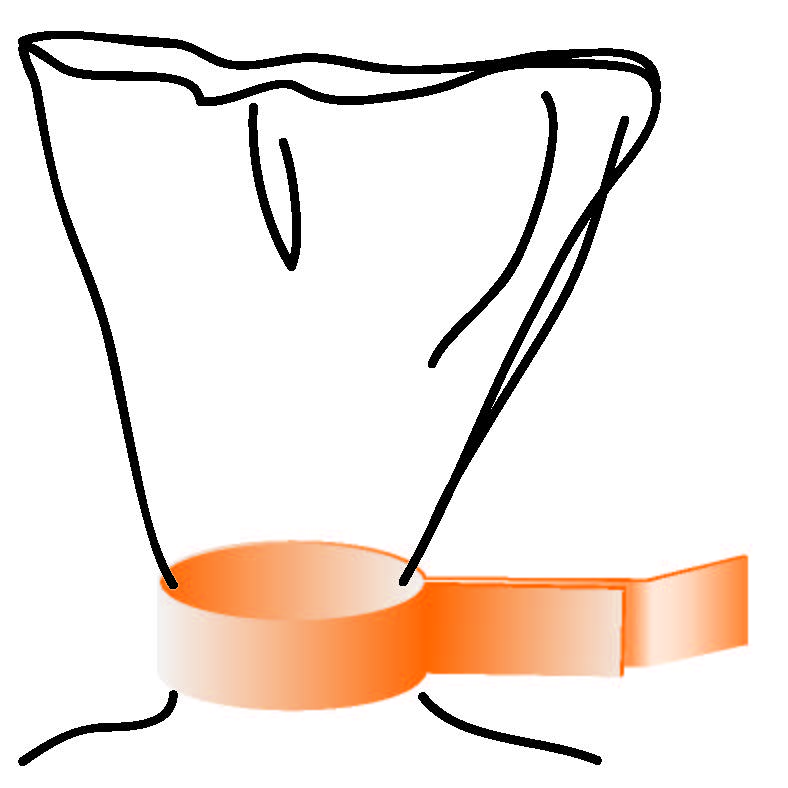

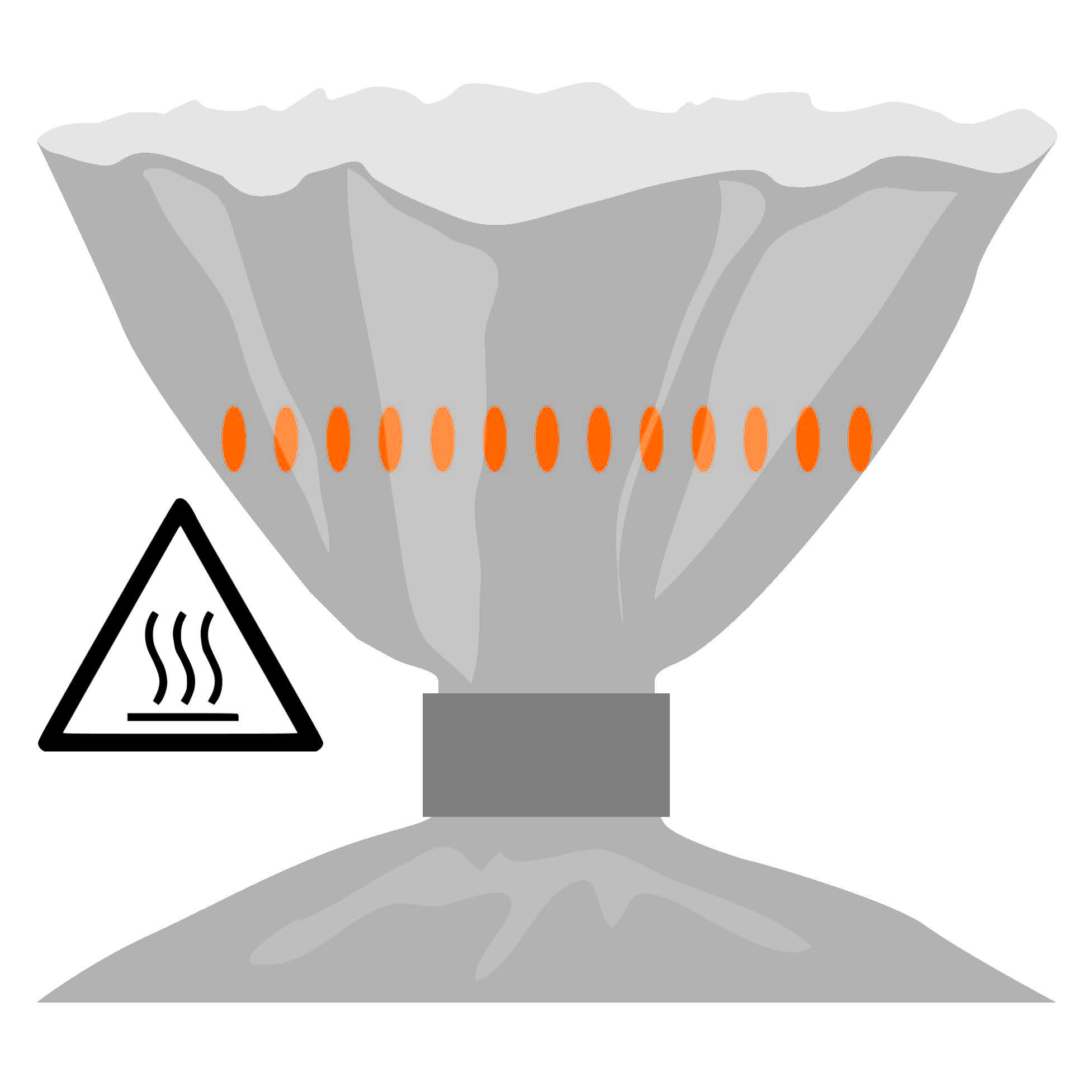

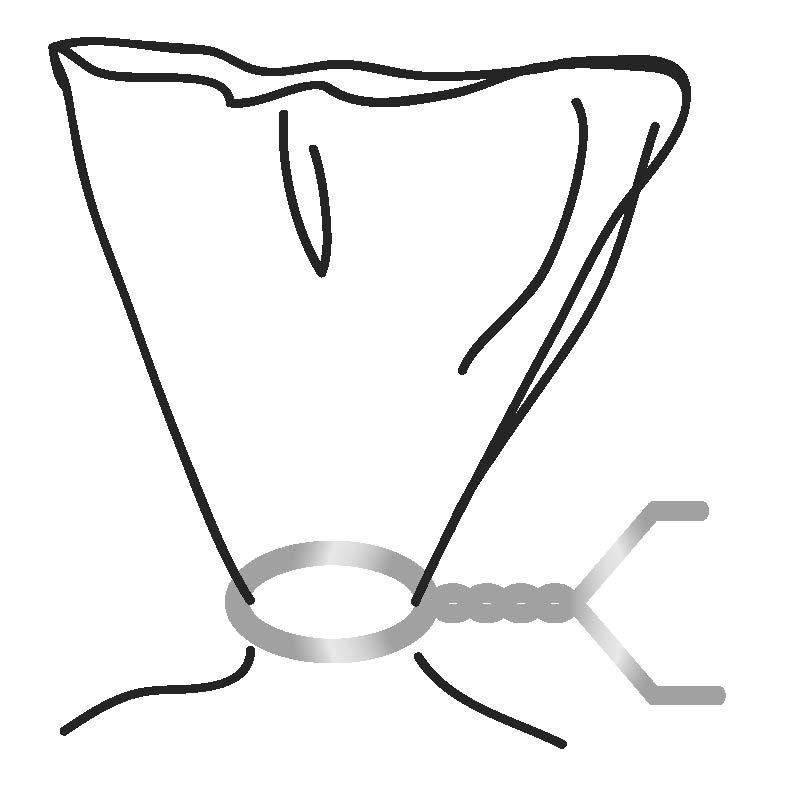

| Closing aggregate for clip |

| Single spool for closure rolls |

| In line discharge conveyor |

| Product outfeed with lateral guides, manually adjustable |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Operating elements located in the machine panel or door of the switch box |

| Omron controls + switches |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

| |

|---|

| Protection hoods made of perforated stainless steel panels |

| Bag opening table with air blower device fixed to the machine frame |

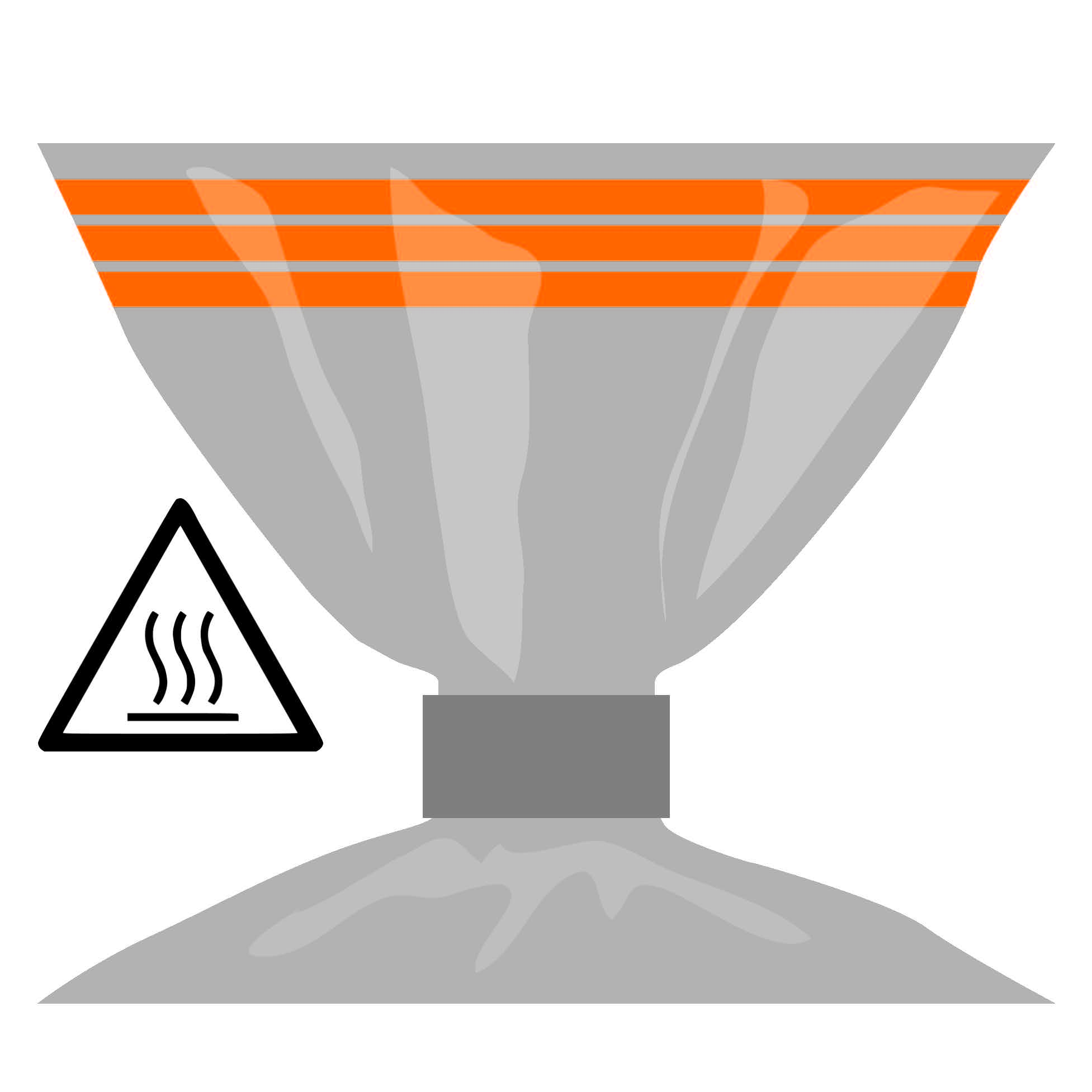

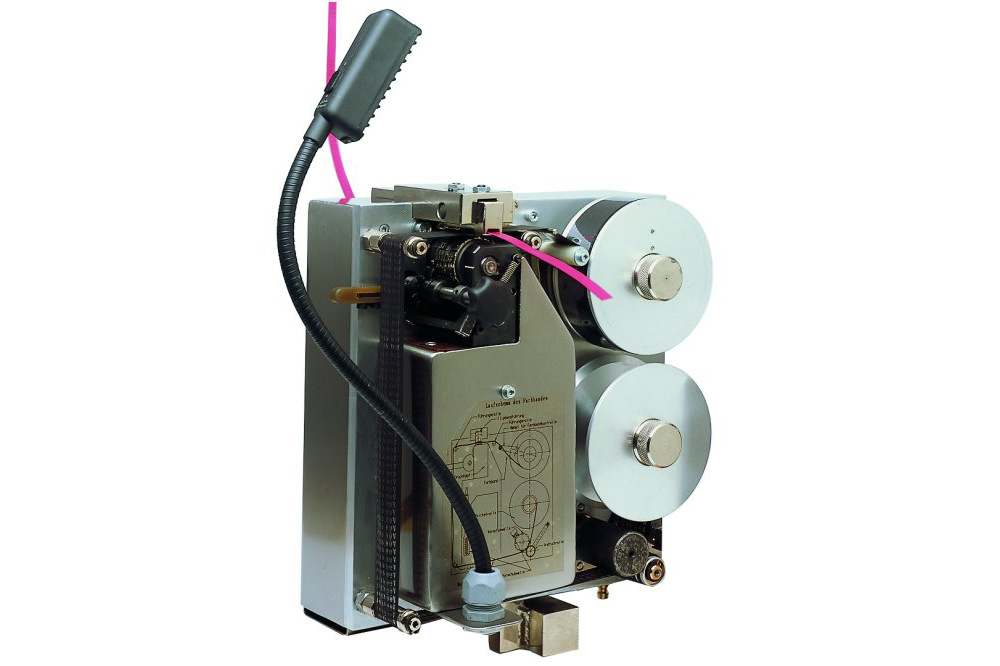

| HPD-Printing on the clip, 6-digit |

| HPD-Printing on the clip, 9-digit |

| HPD-Printing on the clip, 13-digit |

| Preparation for retrofitting an HPD printer (without printer, printer assembly or commissioning) |

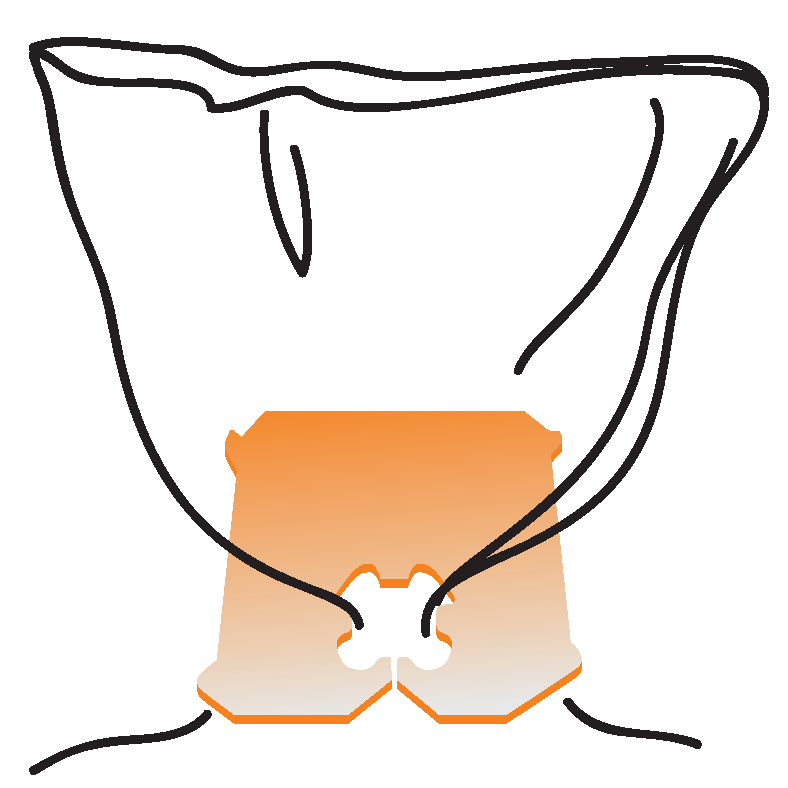

| Closing unit for closures Kwik-Lok® type J-NRP, Schutte Clipps G or equivalent |

| HPD printer, 6 digits for Kwik-Lok®, Schutte Clipps G or equivalent |

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

EC 104

The concept of this device is particularly characterised by the fact that packaged products (tray packages, baguettes, sausages, etc.) are taken from a horizontal packaging machine into the line, closed, and fed into the collecting station at table height.

Rollers and the compact design make this closing unit flexible, usable in any location. All drive elements are directly accessible simply by opening the machine doors. The closing unit is impulse-controlled, has its own drive, and requires no synchronisation with the packaging machine.

The product is transported on conveyor belts, and this process is infinitely adjustable. In combination with a bagging table, this device is also ideally suited for manual loading.

| | |

|---|---|

| Dimensions: | Length: approx. 1400 mm, Width: approx. 1000 mm, Height: approx. 1270 mm, Working height: approx. 850 +70 mm |

| Weight: | 250 kg |

| Product dimensions: | Length: 100 -600 mm, Width: 50 - 180 mm, Height: up to 130 mm |

| Capacity: | up to 2400 packages /h |

| Speed: | adjustable |

| Controller: | Contractor control |

| Operating panel: | Switches and buttons |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power consuption: | 1 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | Pre-manufactured plastic bags, or paper bags (paper with clip closure only) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |