BGA

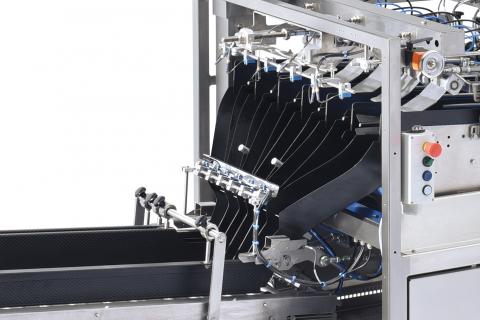

Bagel straighten up and grouping system - BGA

Pictures

Drawings

Standards

Standard specification

|  |

|---|

| Welded machine frame, stainless steel, overall width transport system 1200 mm |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Security light barrier at the infeed area for intervention protection |

| Footrests without dowel holes |

| Conveyor system with adjustable speed |

| Plastic modular belt for product feeding, 1 lane, swiveling |

| Lateral guides above transport conveyor, manually adjustable 1-lane |

| Driven swinging arm divider, 1 lane |

| Stopping units for products at the infeed, driven, 6-lanes |

| Slide unit with turning up device, 6-lanes, alignment of the products to the bag opening |

| Stopping units for products at the outfeed top side, driven, 6-lanes |

| Stopping units for products at the outfeed bottom side, driven, 6-lanes |

| Outfeed equipped with chain conveyor with pusher bars, base plate made from structured stainless steel. |

| Signal lamp - red light / green light |

| Signal lamp - white light |

| Signal horn |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Omron controls + touchpanel in the bagging machine |

| Control unit integrated in the bagging machine |

| Automatic Stand-By control system for behind located machines in case of missing products |

| Frequency converter Hitachi |

| Servocontroller Omron (for swinging arm, line divider 1-spurig) |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

|  |

|---|

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| Frequency converter Allen Bradley |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

BGA

Modular system for the automatic distribution of bagel products from one or more infeed lanes to a higher number of transfer lanes in order to group, set up and align them before they are fed into the packaging.

The device allows easy selection of different recipes and grouping formats and has a design that guarantees easy access to the inside of the device for cleaning and maintenance tasks.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 6200 mm, Width: approx. 1200 mm, Infeed height approx. 1220 mm, Output height approx. 1000 mm |

| Product dimensions: | Diameter: min. 4 inch (92 mm), max. 5 inch (130 mm), Height min. 20 mm, max. ca. 35 mm |

| Capacity: | ca. 15000 bagel/ h (product specific) |

| Speed: | adjustable |

| Controller: | Omron |

| Operating panel: | Switches and buttons |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Servo-controler: | Yaskawa |

| Pneumatic system: | Festo |

| Power supply: | 400 Volts / 50 cycles |

| Power consuption: | approx. 2 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | automatic |