Scan 2

Scanner with integrated checkweigher - Scan 2

Pictures

Drawings

Standards

| |

|---|

| Welded machine frame - heavy duty, stainless steel , standard |

| Welded machine frame, stainless steel, height adjustable 850 - 950 mm |

| Hasp locking for cover panels |

| Footrests without dowel holes |

| Conveyor system with servo driven speed |

| Smooth transport belt |

| Compressed air service unit and valve installed in a separate housing |

| Stainless steel switch cabinet |

| Protective covers made of stainless steel panels |

| Radiation protection hood |

| Radiation protection hood for density scanner system |

| X-ray camera: Function principle Tdi; 2048 x 128 Pixel |

| Power X-ray tube up to 600 W; 60 KV; 10 mA stepless adjustable |

| High performance industrial X-ray unit with metal-ceramic X-ray tube |

| X-ray tube cooling with heat exchanger system air/ water and internal water circulation |

| High precision weighing by use of electro-magnetic force restoration (EMFR) |

| Friction free current connection to the weighing cell |

| System prepared for calibration procedure module B, MID Directive 2004/22/EC |

| Reject unit with lockable collection trough - installed below the transport level |

| Customer-specific electric equipment: System designed in IP65 for wet cleaning |

| Signal lamp - yellow light (X-ray in operation), self-proofing |

| Signal lamp - red / green |

| cable identification marking |

| Switch cabinet with hasp locking |

| Integrated emergency functions by hardware switches |

| Controls + touchpanel OCS |

| Control system for all real-time operations |

| High performance digital image processing |

| 15` touchscreen installed into a swiveable stainless steel housing |

| Switchable visualisation standard/ oversized letters |

| Menue-guided operation with plausibility check. Display of relevant actual data and settings |

| Malfunction message in plain text |

| Wide display of the production figures |

| Memory for up to product parameters (optional extendible) |

| Alarm signal for detection of a serie with equal failures |

| Fine-tuning calibrating of the circular slicer with use of the sliding arithmetic average; transmission of the average amplitude and the arithmetic average |

| software module `clip detection` and `position verification` |

| software module `filling status` and `package verification` |

| Potential-free contacts for circuit signaling with local components |

| Additional emergency stop circuit |

| Ethernet-connection for remote maintenance and for line related statistic data |

| Electric execution according to CE-specification |

| 2 sets of standard inspection boards stainless steel |

| 2 sets of standard inspection boards (customer choice) |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

| |

|---|

| X-ray tube cooling with heat exchanger system water/ water and internal water circulation |

| System prepared for confirmation (MP) of the possibility for a calibration procedure module B, MID Directive 2004/22/EC |

| MID - Calibration with original products |

| Outfeed conveyor equipped with a pusher for rejects , #1 |

| Outfeed conveyor equipped with a pusher for rejects , #2 |

| Sensor for filling level within the collection box incl. counter and signal |

| Sensoring of the product flow (PSK), Checking infeed, rejects and outfeed to avoid foreign packages incl. fast stop function |

| Sensor for reverse flow within the infeed of the collection box incl. signal |

| Additional signal lamp |

| Picture data storage as jpg-formate |

| Comscale4 software package `Basic` ®- connection of up to 5 OCS systems. Local MS-SQL-data server required |

| Software module `Report designer`: Supply of sample forms for statistics made within intervals, time frequence, spot checks or general purpose |

| Data transfer to internal FTP-server for doczumentation purpose of all production figures |

| Licence for the line with functions: Connection X-ray with the central Comsale®-module. Automatic safety storage of data for evaluations and analyses |

| Product examination by use of texture inspection for wholes and stacking faults |

| software module `foreign objects detection` |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

FAQ

Scan 2

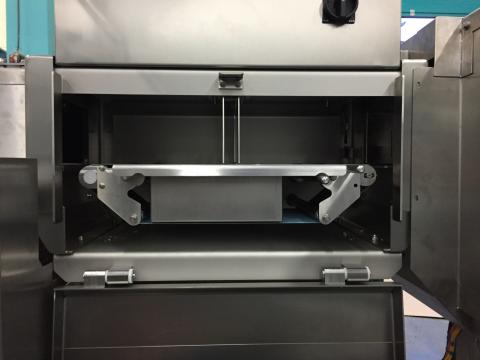

Industrial X - ray system based on the TDI principle (Time Delay Integration) for packaged breads with integration into the Hartmann cutting system. Body in stainless steel with solid tube frame for better absorption of spurious vibrations. Depending on the equipment different combinable control and reject systems are available. Machine operation without active X-ray radiation is possible via customer binary input.

In order to be able to guarantee the assured functionality and the detection accuracy of the X-ray scanner, product and packaging-specific properties must be clarified and specified in detail before the order is placed. Product and packaging-specific changes after commissioning of the X-ray scanner must also be specified on a customer-specific basis.

| | |

|---|---|

| Dimensions: | Length: approx. 2500 mm, Width: approx. 850 mm, Height: 2100mm |

| Product dimensions: | Customer specific - Length: 40 - 100 mm, Width: 160 - 200 mm, Height: 90 - 130 mm |

| Capacity: | approx. 65 bags/min |

| Speed: | adjustable |

| Controller: | OCS |

| Operating panel: | Touchscreen |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | approx. 3 kW |

| Operating side: | left / right |

| Protection class: | IP 65 |

| Adjustment: | manual |