STV 41

Stacking machine - STV 41

Pictures

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, stainless steel, overall width transport system 1100 mm |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Footrests without dowel holes |

| Conveyor system with adjustable speed |

| Top pressure transport device to flatten products like pita-bread or similar - consisting of driven bottom conveyor and a sloping top pressure conveyor |

| Slide with flip over device and ejection function, 3-lane |

| Collecting dip trays, manually removable |

| Belt conveyor for product acceleration |

| Lateral guides above transport conveyor, manually adjustable 3-lanes |

| Product stacker consisting baffle plate, rake for pilling and twin product lifter - 3 lanes |

| O-Belt conveyor for product stack outfeed |

| Outfeed with plastic modular belt conveyor, closed smooth surface, driven |

| Product outfeed with lateral guides, manually adjustable |

| Signal lamp - red / green |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Comfort-operating panel, rotatable with support arm system |

| Controls + touchpanel Omron |

| Operating panel for manually input with Emergency -stop push-button |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Protection hoods made of perforated stainless steel panels |

| Slide with flip over device and ejection function, 2-lane |

| Slide with flip over device and ejection function, 4-lane |

| Modular belt for product acceleration |

| Lateral guides above transport conveyor, manually adjustable 2-lanes |

| Lateral guides above transport conveyor, manually adjustable 4-lanes |

| Product stacker consisting baffle plate, rake for pilling and twin product lifter - 2 lanes |

| Product stacker consisting baffle plate, rake for pilling and twin product lifter - 4 lanes |

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| Frequency converter SEW |

| Frequency converter Allen Bradley |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

FAQ

STV 41

Fully automatic machine for forming product stacks especially for flat round products like Lebanese bread. The standard version can be extended to meet special requirements depending on the output requirements and product format. The large individual products are continuously fed in the direction of travel and stacked in a controlled manner. The product stacks are forwarded one after the other in a controlled manner to the following processing devices.

The clear and easily accessible design allows easy adjustment, cleaning and inspection.

Technical specifications

| | |

|---|---|

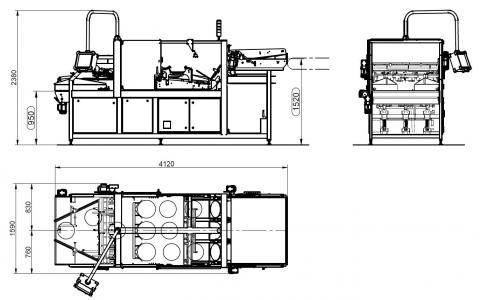

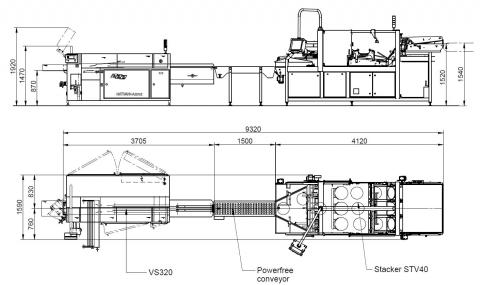

| Dimensions: | Length: approx. 4100 mm, Width: approx. 1600 mm, Height: approx. 2300mm |

| Product dimensions: | Diameter: 170 - 400 mm, Thickness: 5 - 20 mm |

| Capacity: | per stacking lane 80 products/min or 20 stacks with 4 products each/min |

| Speed: | adjustable |

| Controller: | Omron |

| Operating panel: | Touch panel /Touch panel of another machine |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 400 Volts , 50 cycles |

| Power consuption: | approx. 5 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |