VBA 40

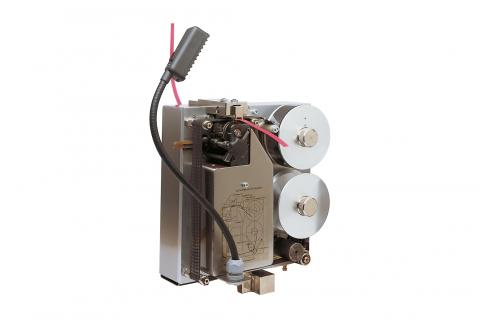

Automatic packaging machine - VBA 40

Pictures

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, lacquered in stainless steel design colour, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Footrests without dowel holes |

| Drive with frequency converter |

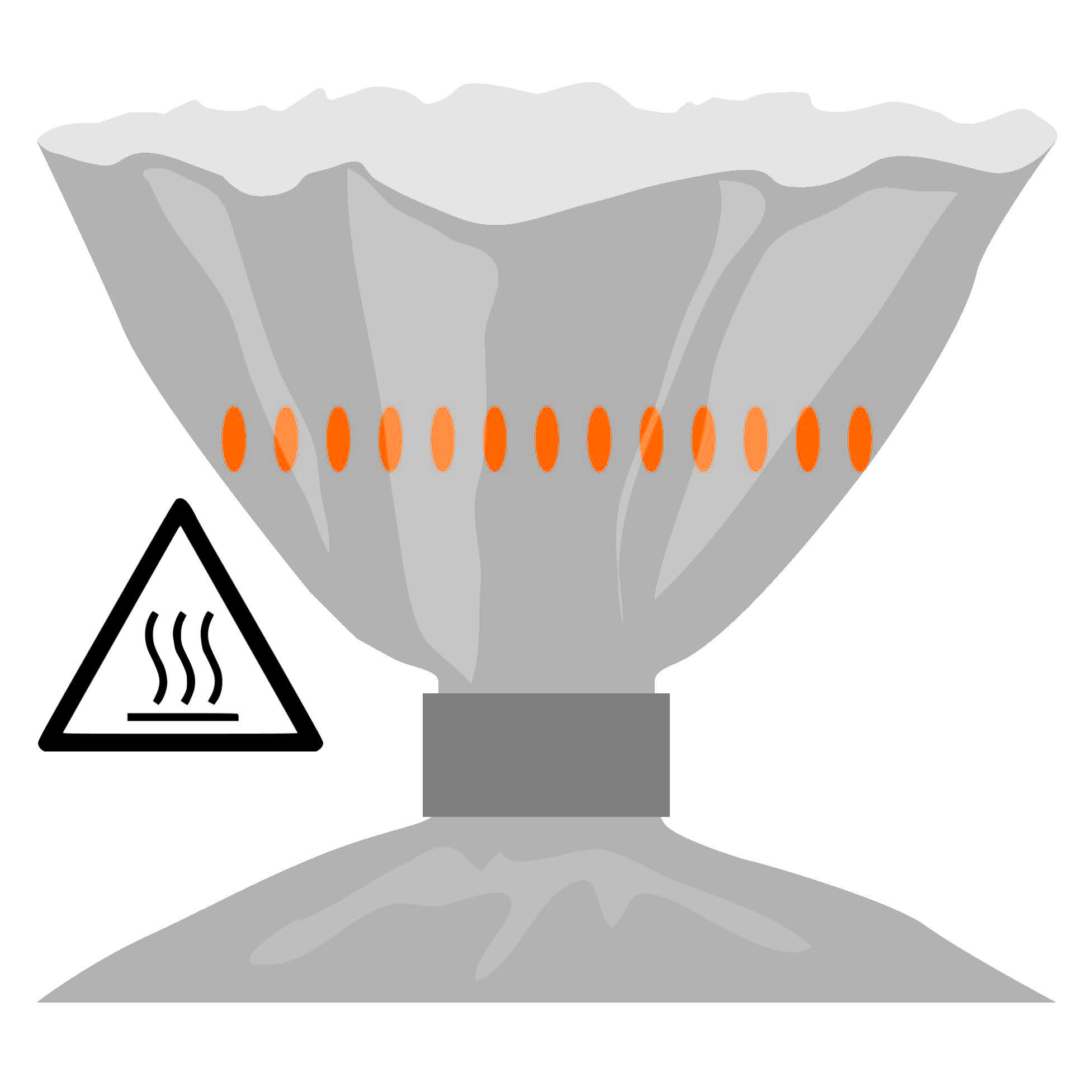

| Funnel adapter for buns, bread rolls or similar products |

| Automatic bag magazine `VBA` for foil bags on a mandrel |

| Automatic infeed and positioning of the next batch of bags |

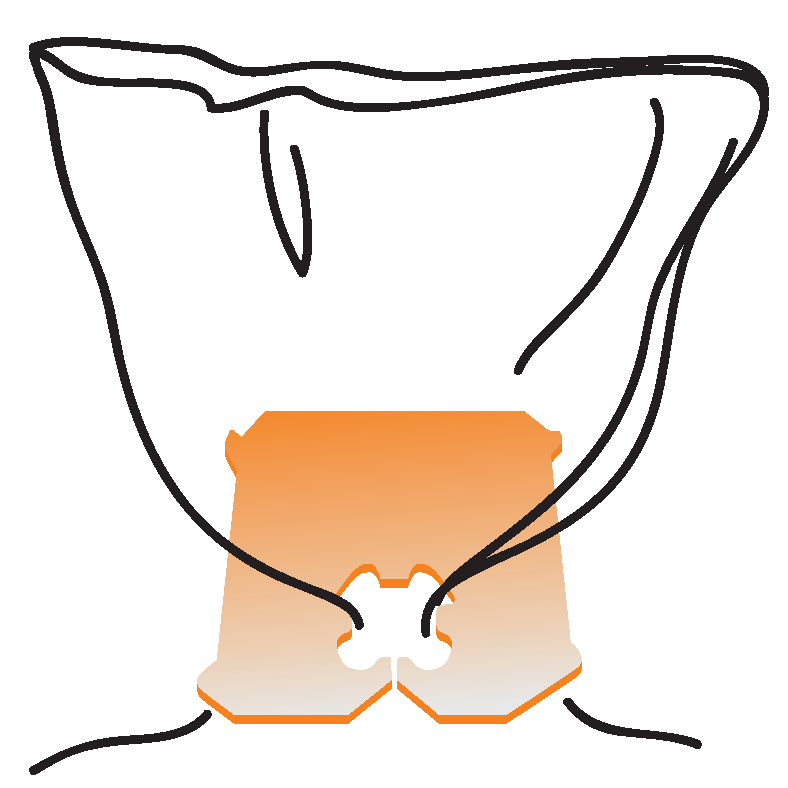

| Single bag lifting device |

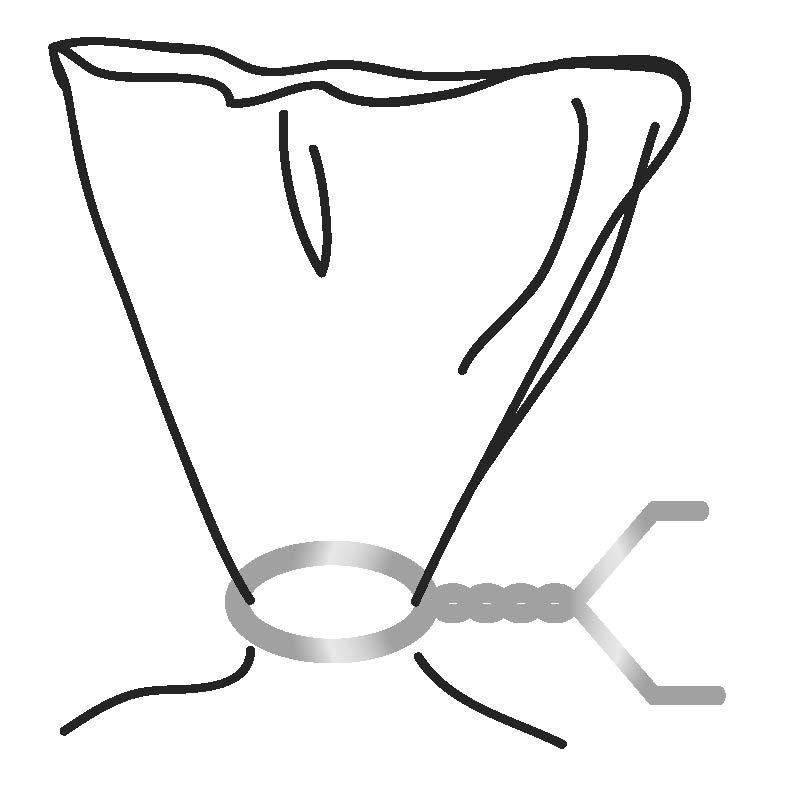

| Set of spreading fingers for bag opening |

| Sensor `bag spanned open for filling at spreader plates` |

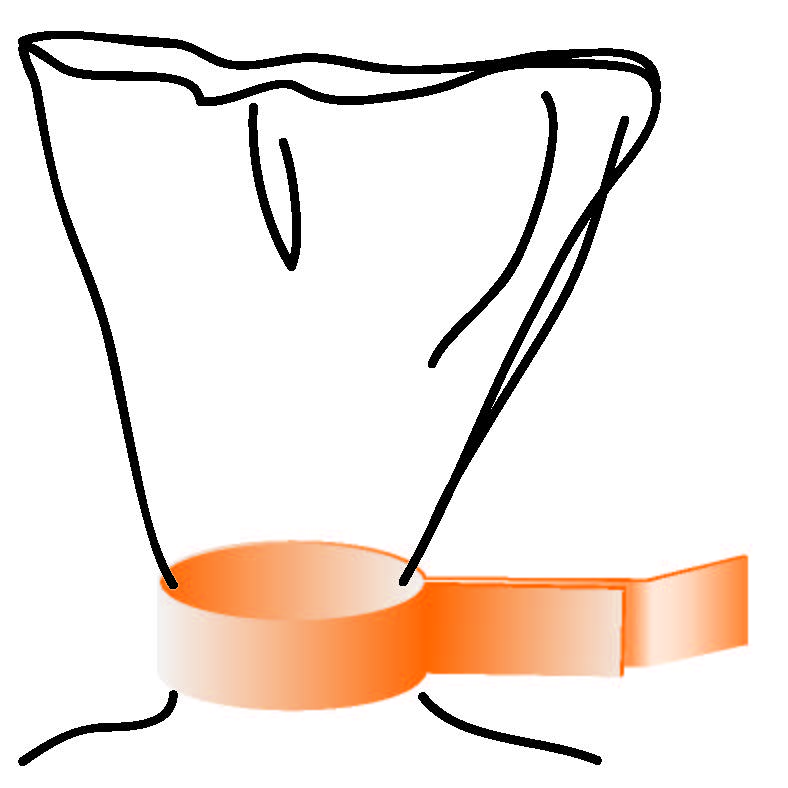

| Closing aggregate for clip |

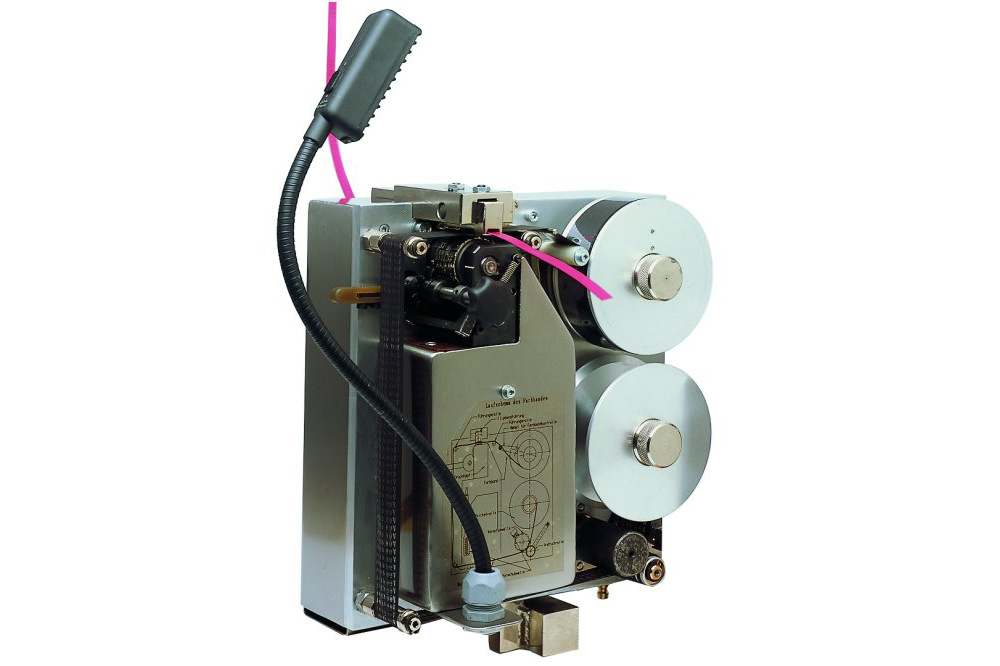

| Single spool for closure rolls |

| In line discharge conveyor |

| Product outfeed with lateral guides |

| Electric socket, (SchuKo) 240V, 16A (or customer-specific) |

| Signal lamp - red / green |

| Switch cabinet with hasp locking |

| Switch cabinet with fan+filter system - standard- |

| Comfort-operating panel, rotatable with support arm system |

| Controls + touchpanel Omron |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Welded machine frame, stainless steel, standard |

| Protection hoods made of perforated stainless steel panels |

| Automatic bag magazine `VBA` for straight U-shaped brackets and cropped U-shaped brackets |

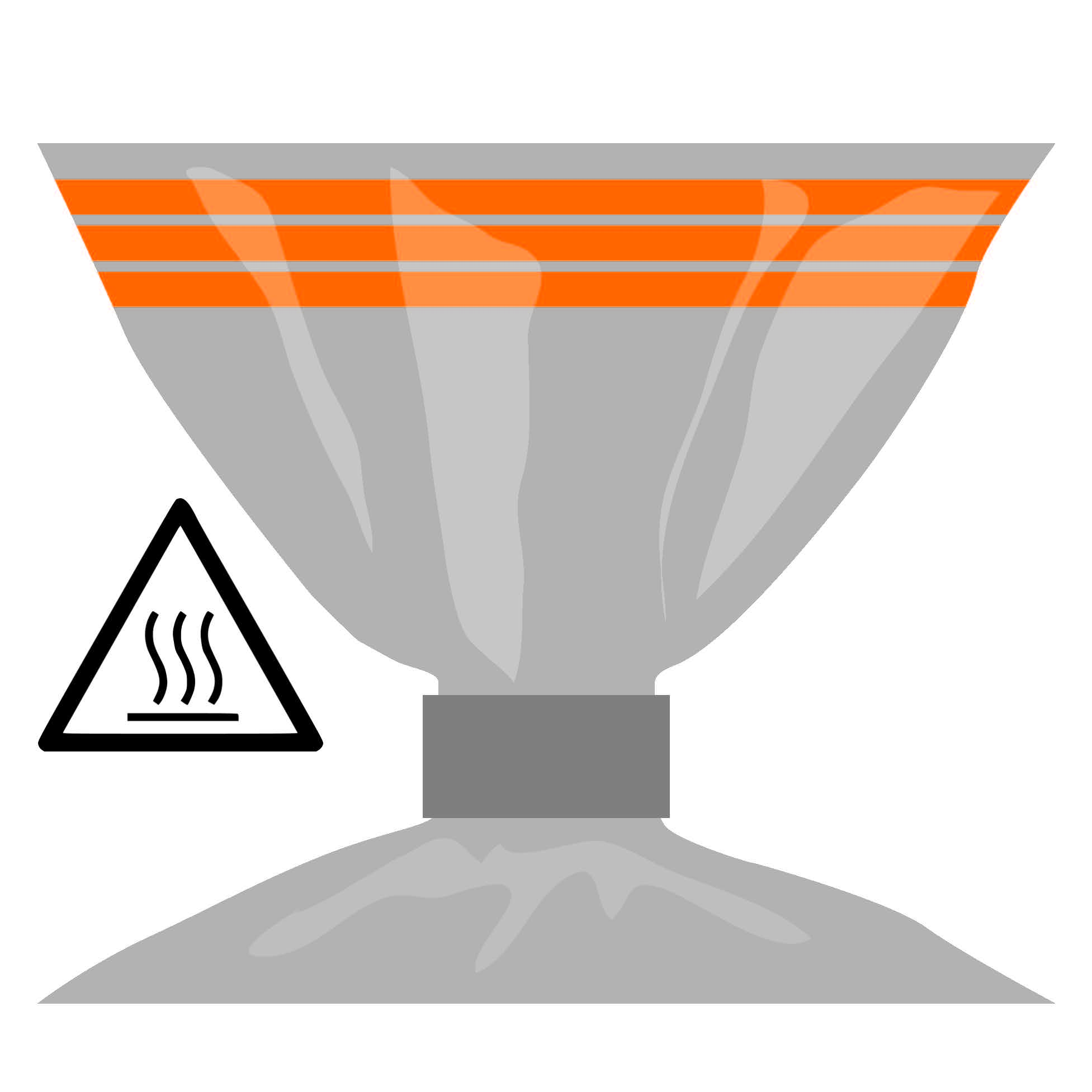

| Tamper proof sealing - Perforating and sealing the frill of the closed plastic bag with a heated comb - 1 row (only in combination with clip-closure or Kwik-Lok ® closure) |

| HPD-Printing on the clip, 6-digit |

| HPD-Printing on the clip, 9-digit |

| HPD-Printing on the clip, 13-digit |

| Preparation for retrofitting an HPD printer (without printer, printer assembly or commissioning) |

| Additional signal lamp |

| Switch cabinet with air-conditioning |

| Frequency converter SEW |

| Frequency converter Allen Bradley |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

VBA 40

This machine is particularly suitable for packaging and closing bulk goods, such as rolls and pastries, in prefabricated bags. Optimal and almost continuous packaging is achieved by combining a solid bag spreading mechanism with a bag magazine for holding up to six prefabricated stacks of bags.

The bag magazine enables the shortest set-up times for changing a stack of bags. The packages closed with the proven HARTMANN closing device, which is characterised by its reliability and long service life.

This packaging machine can be combined with an automatic counting or weighing machine or loaded manually.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 2470 mm, Width: approx. 2500 mm, Heigth: approx. 1205 mm, Loading height: approx. 980 mm |

| Weight: | 700 kg |

| Product dimensions: | Length: 60 - 300 mm, Width: up to 260 mm, Height: 20 - 150 mm |

| Capacity: | Plastic bags: up to 3000 Packages /h Paperbags up to 2400 packages /h |

| Speed: | adjustable |

| Controller: | Omron |

| Operating panel: | Touchscreen |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | 3,5 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | pre-manufactured plastic bags, or paper bags (paper with clip closure only) |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |