KM 600 P

Circular blade slicing machine - KM 600 P

Pictures

Drawings

Standards

|  |

|---|

| Welded machine frame, stainless steel, standard |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Separated compartments for the drive unit and the slicing system - Direct access to the slicing compartment for cleaning or disc-blade exchange |

| Slides and/or funnels for bread crumbs |

| Footrests without dowel holes |

| Infeed conveyor system with servo driven speed |

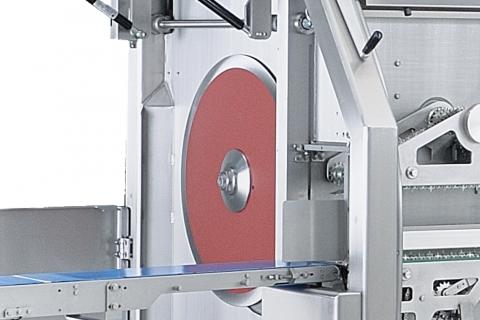

| Servo-driven disc slicer |

| Main gearbox equipped with a differencial drive to seperate control the circumferential speed of the disc slicer |

| Transport belt at the infeed together with TRKM2 or TRKM 3 (for loaf length up to 3 m) |

| Sprocket chain conveyor for product infeed, removeable upper transport and bottom transport - with attachment bracket system for external cleaning |

| Grid cable tray, open design above the machines |

| Top belt height, driven adjustable |

| Disc blades for KM 600 |

| Full-automatic, precise adjustable clocked spay-oil application |

| Oil application system with reservoir in the machine |

| Slicing compartment with additional sensors with mechanical safety locking for openings |

| Local supplied suction system: Crumb suction above and beside the infeed, collecting funnel below the slicer for crumbs and endpieces. Pipeworks up to the central connection point for connection to local suction system. Installation by customer |

| Local supplied suction device for oil mist from above the slicer housing for connection to local suction system. Installation by customer |

| Signal lamp - red light / green light |

| Signal horn |

| Switch cabinet with hasp locking |

| Switch cabinet located separate (max. 6 m) |

| Switch cabinet with air-conditioning |

| Evaluation of data provided by the scanner system |

| Control unit integrated in the Portioning system |

| Servocontroller Omron |

| Automatic Stand-By control system for behind located machines in case of missing products |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

|  |

|---|

| Pusher system for endpieces (back end), driven fork unit |

| Central oil supply system, located separate from machines |

| Illumination of the working area inside the machine |

| Switch cabinet with service interface FrontCom® with LAN and power socket |

| Additional signal lamp |

| Remote service, VPN-Switch INSYS, (Master unit) |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

KM 600 P

For automatic cutting of all bread bars in a continuous process.

The KM 600 P is a logical extension of our tried-and-tested high-performance KM 600 cutting machine. To enable weight-optimized portioning, this machine is prepared for expansion with high-precision control and process components.

The supplied bread bars are first analyzed in an upstream density scanner and then weighed in a separate station.

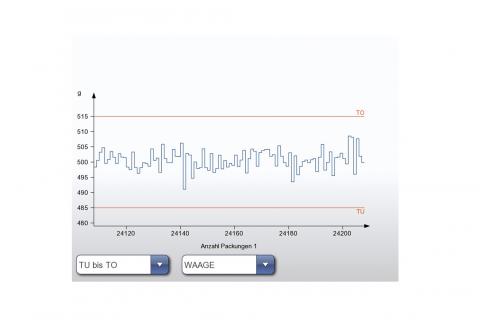

The specific density profile of each bread bar is transferred to the controller of the circular slicing machine. Servo-controlled actuators are used to precisely adjust the slicing thickness in a continuous process. Through these individual adjustments, even free baked bread loafs can be weight-optimized and economically portioned.

The characteristic parameters are constantly stored and are available for every single bread bar. Documentation of the parameters provides additional control over upstream processes (e.g., dough application, recipe changes, ambient temperature) and makes the manufacturing process more transparent.

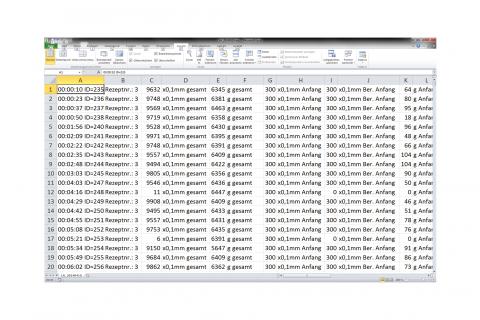

The data can be stored for later archiving either in Excel® format or in a BDE database.

| | |

|---|---|

| Dimensions: | Length: 5590 mm, Width: approx. 2000 mm, Height: 2270mm, Infeed height: 1050 mm |

| Weight: | 1800 kg |

| Product dimensions: | Length: approx. 1480/ 3000 mm, Width: 60 - 200 mm, Height: 80 - 180 mm |

| Capacity: | adjustable up to 600 cuts/ min |

| Speed disc slicer | adjustable |

| Dia. Cutting disc | 680 -750 mm |

| Controller: | Omron |

| Operating panel: | Touchscreen within panel of the portioning system |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Servo-controler: | Yaskawa |

| Pneumatic system: | Festo |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | approx. 9 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Operating side: | left |

| Protection class: | IP 54 |

| Adjustment: | automatic |