PP 30

Machine for pillow packaging - PP 30

Pictures

Drawings

Standards

Standard specification

| |

|---|

| Welded machine frame, stainless steel, overall width transport system 920 mm |

| Switch cabinet located on top of the machine frame |

| Panels, doors and electrical cabinet or switchbox made from stainless steel |

| Hasp locking for cover panels |

| Protection hoods made of polycarbonate |

| Footrests without dowel holes |

| Conveyor system with adjustable speed |

| Plastic modular belt for product infeed |

| Product infeed with lateral guides on both sides consisting of driven belts, manually adjustable |

| Plastic modular belts beside each lengthwise sealing unit, adjustable position in width |

| Film magazine 2x 2 rolls with automatic film change and extendable film carriers, pneumatic clamping |

| Film unwinding station at the top and bottom with roll-off resistance |

| Manual set-up mode for film infeed |

| Preparation of signals and supply for on-site printers (according to customer specification, without printer, printer assembly or commissioning) |

| Crosswise sealing station can be pulled out laterally |

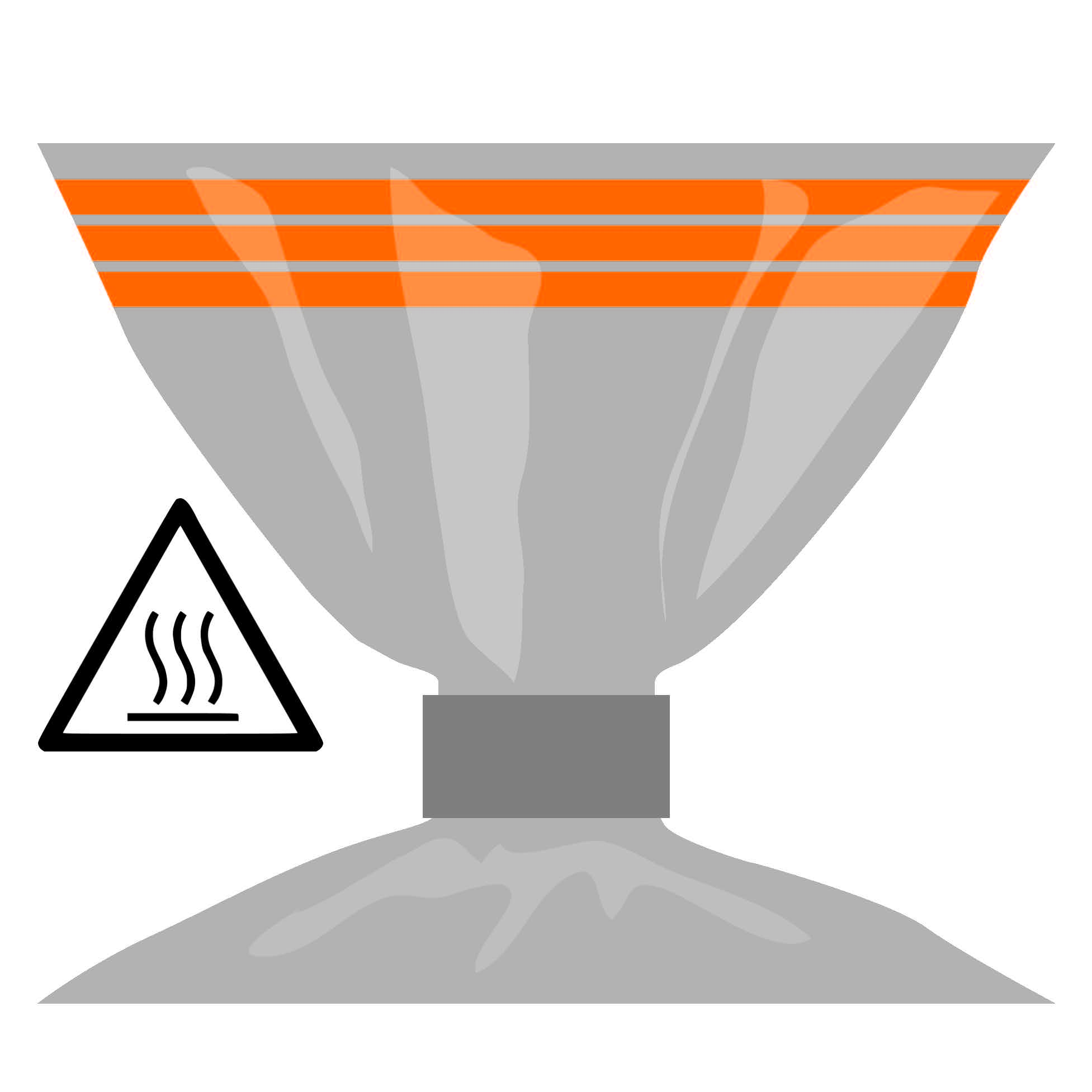

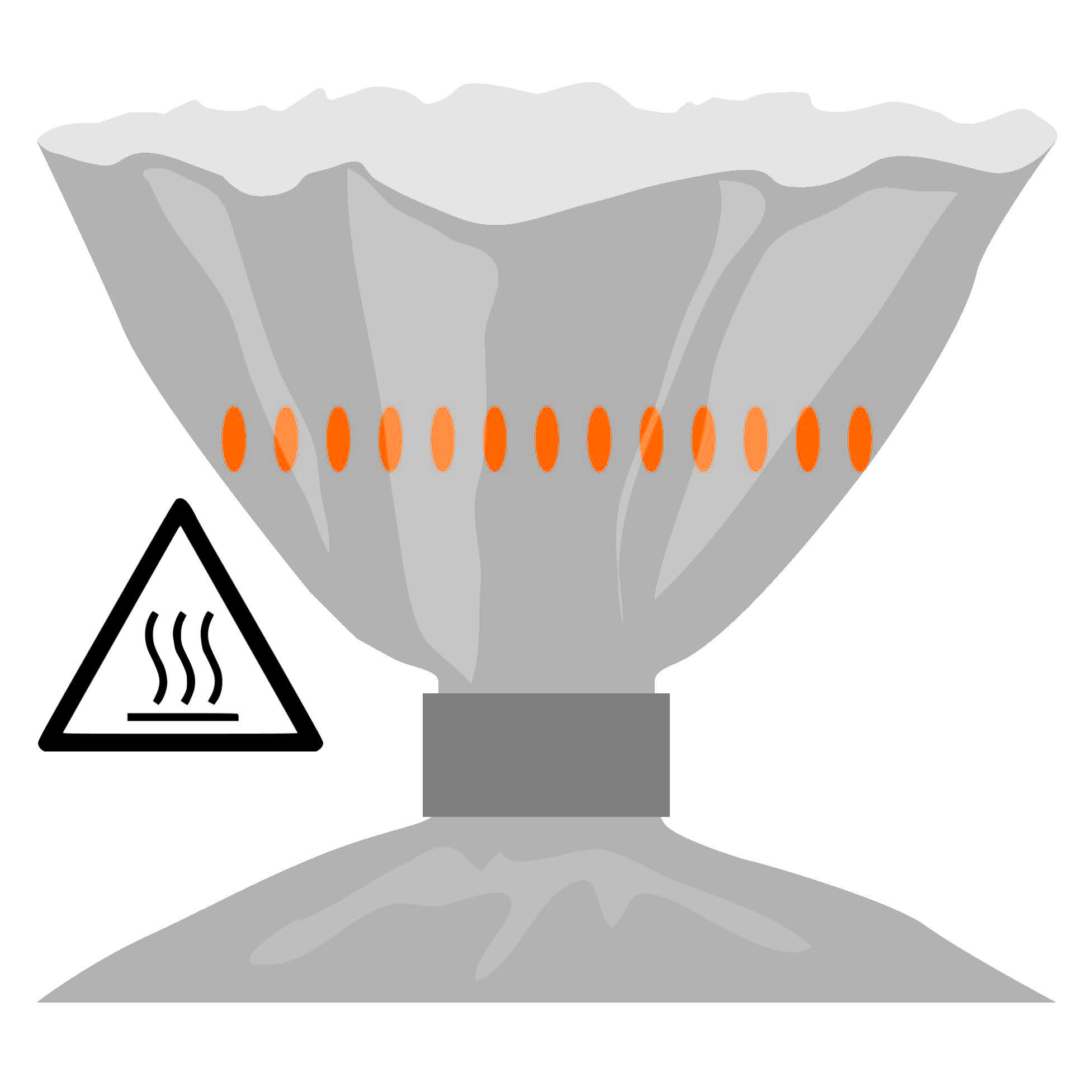

| Pulsed heating of sealing wires - sealing lengthwise and crosswise, PE-foils |

| Plastic modular belt behind crosswise sealing station |

| Plastic modular belt within the sealing unit, 1-lane |

| Air extractation from the pack via suction channels on both sides |

| Integratedside channel blower device - enlarged version |

| Plastic modular belt for the outfeed, 1-lane |

| Sterile filter for sterilization the compressed air coming into contact with the products |

| Illumination of the working area inside the machine (if doors are opened) |

| Switch cabinet with service interface FrontCom® with LAN and power socket |

| Signal lamp - red / green |

| Signal horn |

| Switch cabinet with hasp locking |

| Switch cabinet with air-conditioning and inside air circulation |

| Comfort-operating panel, rotatable with support arm system |

| Controls + touchpanel Omron |

| Automatic Stand-By in case of missing products |

| Frequency converter Hitachi |

| Electric execution according to CE-specification |

| Operating language and labels in German language |

| Operating manual in German language |

| Spare parts catalogue in German language |

Optionen

Options

| |

|---|

| Switch cabinet located separate (max. 6 m) |

| Plastic modular belt for product infeed designed in IP65, removable for wet-cleaning, incl. transport trolley |

| Ionisation device for plastic foils (Keyence) |

| Permanent heated sealing plates, non-stick coated - PP-foils lengthwise and crosswise |

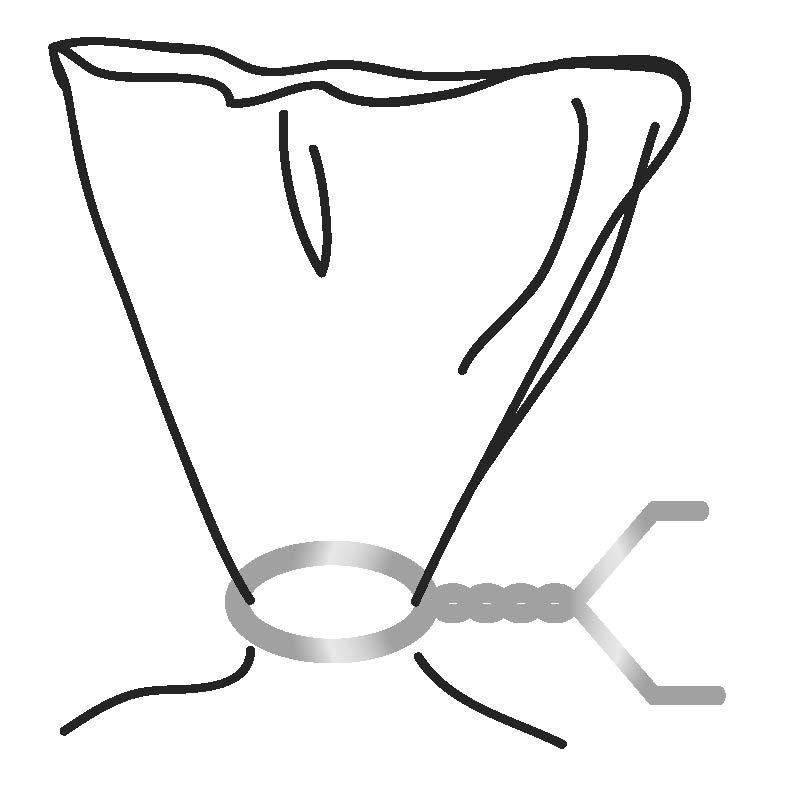

| Double middle sealing beam with cutting knifes, permanent heated sealing plates, non-stick coated - PP-foils |

| Double middle sealing beam, pulsed heating of sealing wires - PE-foils |

| Double middle sealing beam with cutting knifes, pulsed heating of sealing wires - PE-foils |

| Extend lengthwise sealing length for oversized Pillow packages |

| Manual sidewise position adjustment for center sealing bar +/- 50 mm |

| Manual sidewise position adjustment for center sealing bar +/- 50 mm incl. pneumatic position lock |

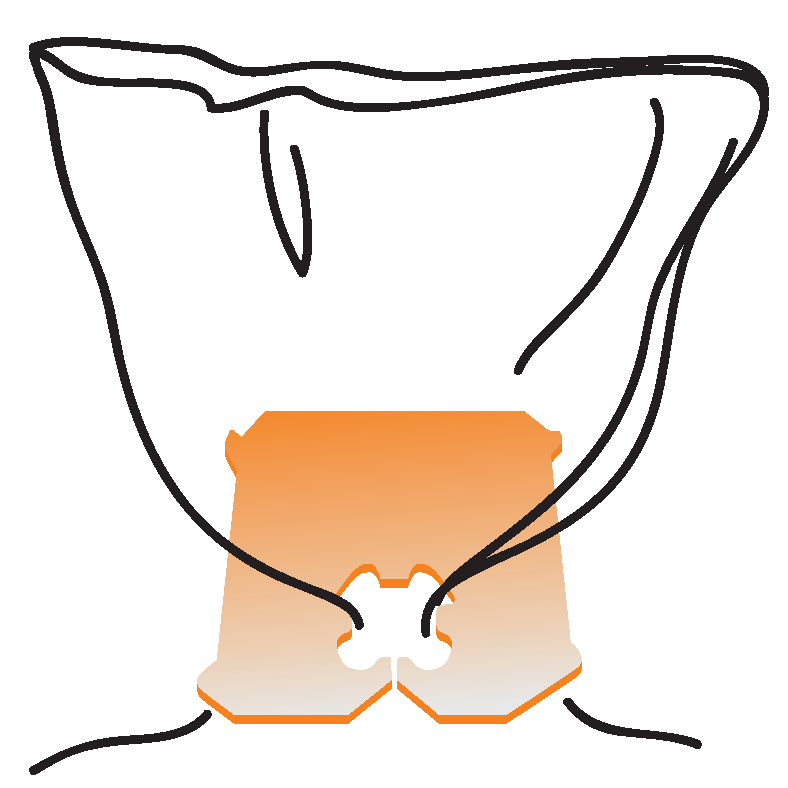

| Clamping device for the external longitudinal sealing - only for defined film types, only in connection with upper cushion pressure (output: up to max. 20 cycles / min.) |

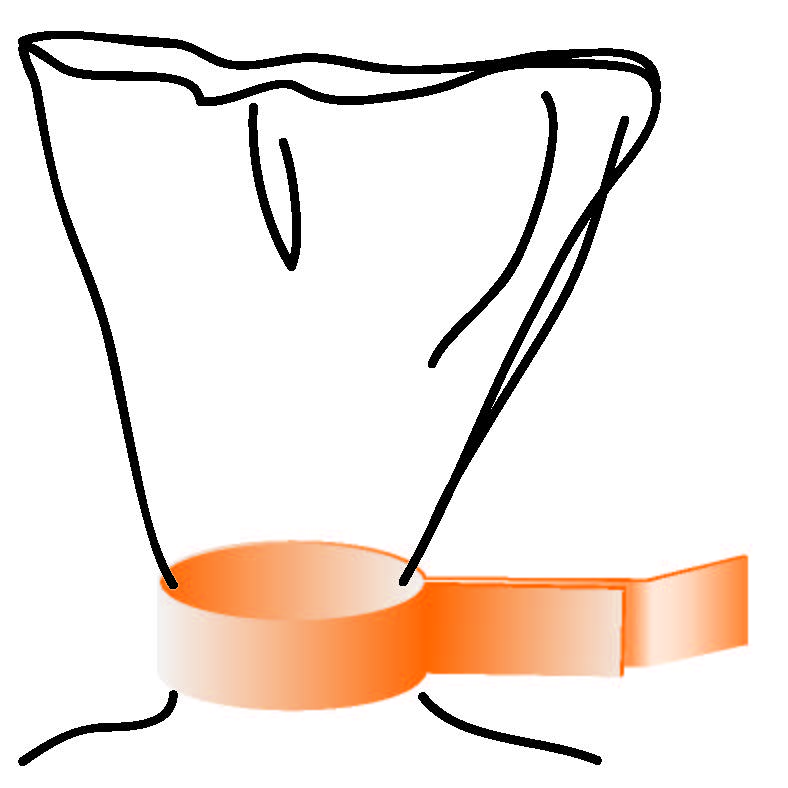

| Cutting off the foil overhang after sealing -for defined films |

| Suction nozzles for cut off foil residues and pipeworks inside the machine, without suction unit |

| Plastic modular belt within the sealing unit, 2-lanes |

| Plastic modular belt within the sealing unit, 2x2-lanes, adjustable in width |

| T-belt conveyors within the sealing unit, multi-lanes |

| Additional signal lamp |

| RFID - Panel access authorization per chip, 10 pieces with up to 5 authorization levels |

| RFID - Additional chip, 10 pcs. with up to 5 authorization levels |

| Frequency converter SEW |

| Frequency converter Allen Bradley |

| Remote service, VPN-Switch INSYS, (Master unit) |

| Voltage modulation, 3-phase |

| Electric execution according to UL-specification |

| Customer-specific special machine modifications |

| Customer-specific operating language and labels |

| Customer-specific operation manually |

Videos

FAQ

PP 30

The HARTMANN PP 30 automatic pillow packaging machine is a modular packaging machine that can be assembled according to customer's requirements.

Variable package sizes with up to 30-40 products meet special market requirements and product-specific conditions. The packaging consists of an upper and lower continuous foil, between which the products are grouped and tightly sealed. Optional sealing units allow subdivisions of the packages with or without separating cut.

The system's modular design enables it to be combined with product slicing systems for slicing and separating slices before packaging. An automatic basket loader is optionally available for after packaging.

Technical specifications

| | |

|---|---|

| Dimensions: | Length: approx. 4600 mm, Width: approx. 2000 mm, Height: 2750mm, Working height: approx. 1050 mm |

| Weight: | approx. 3700 kg |

| Product dimensions: | Diameter / width: min. approx. 50 mm, Length: up to 350 mm, Height: 20 - 80 mm |

| Capacity: | approx. 30 pillows/min (400x600) product specific with up to 30 -40 products / pillow |

| Speed: | adjustable |

| Controller: | Omron |

| Operating panel: | Touchscreen |

| Control voltage: | 24 V, DC |

| Frequency controller: | Hitachi |

| Pneumatic system: | Festo |

| Power supply: | 230/400 Volts / 50 cycles |

| Power consuption: | 7-10 kW |

| Compressed air: | min. 6,0 bar (ISO 8573-1) |

| Packing material: | PE , PP, cPP, BOPP |

| Operating side: | left / right |

| Protection class: | IP 54 |

| Adjustment: | manual |

| Special: | Pillow dividing sealing single/twin w/o cutting |